- Home

- Building Material

- Concrete

- A platform for growth

A platform for growth

The growth in the worldwide construction market is giving rise to a surge in demand for concrete products, pipes and shafts as well as precast components. This demand is in turn boosting developments among machinery and plant manufacturers. At bauma 2013, to be held in Munich from April 15 - 21, 2013, a whole range of new products made of concrete and other materials will displayed at the booths of systems suppliers and components specialists, across the spectrum from newcomers to market leaders.

Organiser

The organiser Messe Mnnchen International is one of the world's leading trade show companies. In Munich alone, it organises around 40 trade shows for capital and consumer goods, and key high tech industries. Each year over 30,000 exhibitors and around two million visitors participate in the events held at Messe Mnnchen exhibition centre, the ICM - International Congress Centre Mnnchen, and in the MOC Veranstaltungs Centre Mnnchen.

Sales growth

The German Engineering Federation Verband Deutscher Maschinenund Anlagenbau (VDMA) expects concrete-block-making machines and systems, for the manufacture of precast concrete components, to be a growth segment in the construction and building materials machinery sector this year. For 2012, the federation predicts a 5 per cent growth in sales in both building materials and construction machinery.

Demand backlog

A recent survey of selected German building materials machinery manufacturers, by the Weimar-based Institute for Applied Research in Building (IAB - Institut fnr Angewandte Bauforschung), reveals that sales growth is expected in overseas markets in particular. Demand is especially strong, in the emerging markets of China, India, certain countries in Eastern Europe and some of the former Soviet Republics. The report identifies strong interest in turnkey production systems where manufacturing expertise and services were also included in the package.

Precast concrete components

Vollert Anlagenbau of Weinsberg has delivered India's first modern pallet circuit system that is currently being used by firm Precast India Infrastructures in its production plant in Pune. This plant produces around 120 sq m of precast concrete walls per hour, as well as precast concrete floors and hollow-core slabs for the subcontinent's booming building industry.

Another current example of German technology installed abroad is Singapore's first fully automated precast concrete plant, which operationalised in May 2012. The system caters to the demand from the residential and industrial building sectors in the rapidly expanding economy of this island state. Key components in this system have been delivered by Vollert Anlagenbau as well as Weckenmann Anlagentechnik of Dormettingen.

Increase in aerated concrete

Another exemplary project in the former Soviet Republics involves the expansion of an aerated concrete factory in the Ukraine, completed in March 2012. The success of this project led the systems manufacturer Masa of Porta Westfalica to increase its daily factory output from 1,000 cu m to 1,400 cu m.

Good prospects for wetcast concrete

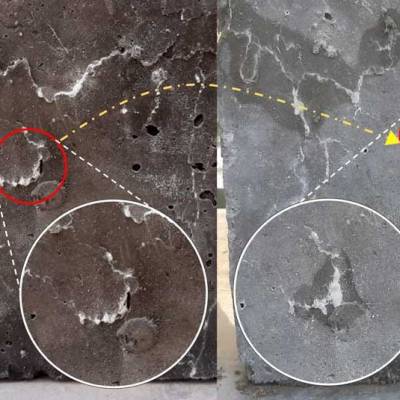

On the subject of new technology, the IAB survey reveals a general rise in market interest in the wetcast production process. Here wet concrete is poured into flexible special moulds which have patterned inner faces. This pattern is retained on the surface of the concrete after curing. The technique enables companies to produce high-quality products with an individual look.

(Communication by the management of the company)

bauma 2013 in Munich will display a whole new range of products made of concrete and other materials. The growth in the worldwide construction market is giving rise to a surge in demand for concrete products, pipes and shafts as well as precast components. This demand is in turn boosting developments among machinery and plant manufacturers. At bauma 2013, to be held in Munich from April 15 - 21, 2013, a whole range of new products made of concrete and other materials will displayed at the booths of systems suppliers and components specialists, across the spectrum from newcomers to market leaders. Organiser The organiser Messe Mnnchen International is one of the world's leading trade show companies. In Munich alone, it organises around 40 trade shows for capital and consumer goods, and key high tech industries. Each year over 30,000 exhibitors and around two million visitors participate in the events held at Messe Mnnchen exhibition centre, the ICM - International Congress Centre Mnnchen, and in the MOC Veranstaltungs Centre Mnnchen. Sales growth The German Engineering Federation Verband Deutscher Maschinenund Anlagenbau (VDMA) expects concrete-block-making machines and systems, for the manufacture of precast concrete components, to be a growth segment in the construction and building materials machinery sector this year. For 2012, the federation predicts a 5 per cent growth in sales in both building materials and construction machinery. Demand backlog A recent survey of selected German building materials machinery manufacturers, by the Weimar-based Institute for Applied Research in Building (IAB - Institut fnr Angewandte Bauforschung), reveals that sales growth is expected in overseas markets in particular. Demand is especially strong, in the emerging markets of China, India, certain countries in Eastern Europe and some of the former Soviet Republics. The report identifies strong interest in turnkey production systems where manufacturing expertise and services were also included in the package. Precast concrete components Vollert Anlagenbau of Weinsberg has delivered India's first modern pallet circuit system that is currently being used by firm Precast India Infrastructures in its production plant in Pune. This plant produces around 120 sq m of precast concrete walls per hour, as well as precast concrete floors and hollow-core slabs for the subcontinent's booming building industry. Another current example of German technology installed abroad is Singapore's first fully automated precast concrete plant, which operationalised in May 2012. The system caters to the demand from the residential and industrial building sectors in the rapidly expanding economy of this island state. Key components in this system have been delivered by Vollert Anlagenbau as well as Weckenmann Anlagentechnik of Dormettingen. Increase in aerated concrete Another exemplary project in the former Soviet Republics involves the expansion of an aerated concrete factory in the Ukraine, completed in March 2012. The success of this project led the systems manufacturer Masa of Porta Westfalica to increase its daily factory output from 1,000 cu m to 1,400 cu m. Good prospects for wetcast concrete On the subject of new technology, the IAB survey reveals a general rise in market interest in the wetcast production process. Here wet concrete is poured into flexible special moulds which have patterned inner faces. This pattern is retained on the surface of the concrete after curing. The technique enables companies to produce high-quality products with an individual look. (Communication by the management of the company)