- Home

- Technology

- Hamm: Construction 4.0

Hamm: Construction 4.0

Read full article

CW Gold Benefits

- Weekly Industry Updates

- Industry Feature Stories

- Premium Newsletter Access

- Building Material Prices (weekly) + trends/analysis

- Best Stories from our sister publications - Indian Cement Review, Equipment India, Infrastructure Today

- Sector focused Research Reports

- Sector Wise Updates (infrastructure, cement, equipment & construction) + trend analysis

- Exclusive text & video interviews

- Digital Delivery

- Financial Data for publically listed companies + Analysis

- Preconceptual Projects in the pipeline PAN India

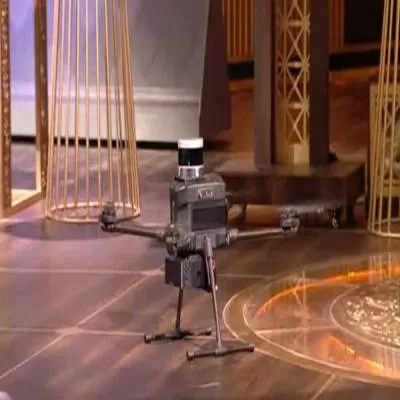

Wirtgen Group’s HAMM is pursuing a holistic approach towards road building, especially compaction, taking into account the ‘hardware’ aspects as well as those relating to ‘software’.HAMM is pursuing a holistic approach taking into account the ‘hardware’ aspects, that is to say trends in machine technology, as well as those relating to ‘software’ such as, for example, questions concerning the role of people in the construction process of the future.“What will the ‘Construction Site 4.0’ look like? What added values can HAMM contribute to BIM as a roller manufacturer? Which mechanical characteristics will be relevant in 10, 20, 30 years’ time? What demands will employees place on their working environment in road building in 2030? In addressing these questions, we are developing our visions for the future of road construction. From these, we generate concrete new concepts and solutions around our core competence, compaction,” says Dr Axel Römer, Head of Research and Development, HAMM. Construction site of the futureDigitalisation, electromobility and globalisation are already changing our world today in many ways. HAMM, at an early stage, equipped the rollers with numerous assistance systems to aid the driver as well as for process documentation and optimisation.An example of this is the compliance with compaction specifications with the aid of the HCQ Navigator. With WITOS HCQ, HAMM is expanding its offering in this area. The new module enables the compaction progress to be monitored – in real-time as well as remotely. HAMM also sees the potential for even more efficiency in the optimisation of machine utilisation with the aid of WITOS FleetView. It facilitates maintenance and diagnostics, speeds up response times in the event of faults and also enables systematic analyses of operating and user behavior. At the same time, unscheduled downtimes, often involving transport costs and organisational work, are avoided.Another approach for the workplace of the future is a remotely controlled compactor that has already been operating for two years at a quarry in Germany. HAMM has for the first time visualised the thinking on the subject in the form of the ‘Autonomous Roller F1’. This is not based on an actual machine, but is a study on the compaction of the future.Future working environmentHAMM has developed the Easy Drive operating concept for the current generations of tandem rollers, compactors and pneumatic tyre rollers. And so, it has succeeded in simplifying and standardising the roller operation and in so doing has taken ergonomics and operator comfort to a new level.Sustainable construction“Protecting the environment and cutting costs often go hand-in-hand,” says Dr Römer. The sustainable compaction offering is already complemented by a range of technologies: For example, with oscillation compaction the number of passes can be reduced. Another example for sustainable construction is the HCQ Navigator. Through process optimisation, it facilitates faster and more homogenous compaction, which ultimately saves energy, time and costs.Optimising compactionHAMM remains committed to its principles and that it will continue to provide the construction industry with innovative solutions in its core competence – compaction – in the decade to come. “As the trendsetter and driving force of the compaction sector we will continue to forge ahead and develop in a sustainable way in the years to come – and that is to say with equal emphasis on asphalt construction and earthwork. To this end, we maintain an active dialogue with our customers and will continue to serve as a partner to the construction industry in the years ahead,” stresses Dr Stefan Klumpp, Chief Technology Officer at HAMM.