- Home

- Building Material

- Concrete

- Truly Concrete

Truly Concrete

One of the leading flooring construction companies delivered India´s first joint-less and non-shrink floor for a pharmaceutical manufacturing company. And, this prestigious project - successfully laid in August 2014 with a total floor area of 19,600 sq ft - was ably supported by Atlas Copco. Having relied on the high performance of Atlas Copco Construction Technique´s concrete equipment in the past, the company chose to use Atlas Copco heavy ride on trowels to ensure that the right finish and expertise was delivered.

Ride on trowels

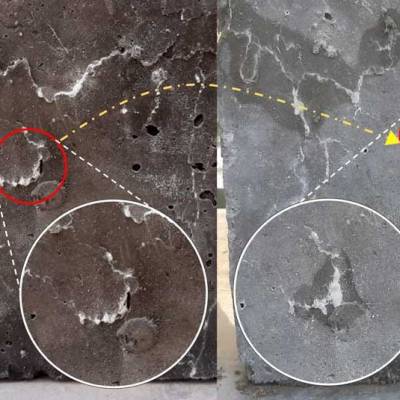

The project required a joint-less and non-shrink concrete floor, which was achieved with a high quality concrete mix design. After achieving the floor finishing with screeds, the floating process was completed with the state-of-the-art heavy duty 650 plus kg, hydraulically controlled with joystick, ride on trowels from Atlas Copco.

BG920 model of ride-on-trowels from Atlas Copco were deployed for the purpose of finishing the floor and achieving a high degree of flatness and compaction. The end product of this project was an innovative floor - thinner, flatter and stronger - with no traces of saw cut joints, expansion joints or cracks. With a 40 to 50 per cent reduction in slab thickness as compared to traditional floors, lower concrete and cement consumption was achieved and the completed floor is now a benchmark in industrial concrete flooring. Further, lesser concrete usage has resulted in heavy reduction in CO2 emission, thereby reducing the carbon footprint.

Best in the league

For the bigger jobs and higher demands, the ride-on-trowels from Atlas Copco Construction Technique deliver higher reliability and best results on big jobs as compared to other trowels in the same class. Its reliability, power and responsiveness are much appreciated features among larger contractors. Features such as robust design, powerful engine and heavy duty gearbox of the BG920 heavy ride on trowels played a vital role in ensuring a smooth floor finish with high abrasion resistance in this project.

Gurdeep Singh Matharu, Marketing Manager, Atlas Copco Light Concrete and Compaction equipment, India, says, ´Our ride-on-trowels deliver the best solutions for such innovative floors. These are the trend setters and the future of flooring technology in India where lighter trowels will be replaced by heavier hydraulic trowels with joysticks.´

Optional accessories such as floating blades, combination blades, smoothing disk (clip-on), smoothing disk (securing catch), lifting sling and transport wheels (dolly jacks) are easily available with Atlas Copco´s ride-on-trowels, which will pave the way for newer business opportunities in the near future.

Heavy ride-on-trowels from Atlas Copco Construction Technique play a vital role in creating a smooth finish and crack-free industrial concrete floor. One of the leading flooring construction companies delivered India´s first joint-less and non-shrink floor for a pharmaceutical manufacturing company. And, this prestigious project - successfully laid in August 2014 with a total floor area of 19,600 sq ft - was ably supported by Atlas Copco. Having relied on the high performance of Atlas Copco Construction Technique´s concrete equipment in the past, the company chose to use Atlas Copco heavy ride on trowels to ensure that the right finish and expertise was delivered. Ride on trowels The project required a joint-less and non-shrink concrete floor, which was achieved with a high quality concrete mix design. After achieving the floor finishing with screeds, the floating process was completed with the state-of-the-art heavy duty 650 plus kg, hydraulically controlled with joystick, ride on trowels from Atlas Copco. BG920 model of ride-on-trowels from Atlas Copco were deployed for the purpose of finishing the floor and achieving a high degree of flatness and compaction. The end product of this project was an innovative floor - thinner, flatter and stronger - with no traces of saw cut joints, expansion joints or cracks. With a 40 to 50 per cent reduction in slab thickness as compared to traditional floors, lower concrete and cement consumption was achieved and the completed floor is now a benchmark in industrial concrete flooring. Further, lesser concrete usage has resulted in heavy reduction in CO2 emission, thereby reducing the carbon footprint. Best in the league For the bigger jobs and higher demands, the ride-on-trowels from Atlas Copco Construction Technique deliver higher reliability and best results on big jobs as compared to other trowels in the same class. Its reliability, power and responsiveness are much appreciated features among larger contractors. Features such as robust design, powerful engine and heavy duty gearbox of the BG920 heavy ride on trowels played a vital role in ensuring a smooth floor finish with high abrasion resistance in this project. Gurdeep Singh Matharu, Marketing Manager, Atlas Copco Light Concrete and Compaction equipment, India, says, ´Our ride-on-trowels deliver the best solutions for such innovative floors. These are the trend setters and the future of flooring technology in India where lighter trowels will be replaced by heavier hydraulic trowels with joysticks.´ Optional accessories such as floating blades, combination blades, smoothing disk (clip-on), smoothing disk (securing catch), lifting sling and transport wheels (dolly jacks) are easily available with Atlas Copco´s ride-on-trowels, which will pave the way for newer business opportunities in the near future.