- Home

- Infrastructure Transport

- PORTS & SHIPPING

- Port of Plenty

Port of Plenty

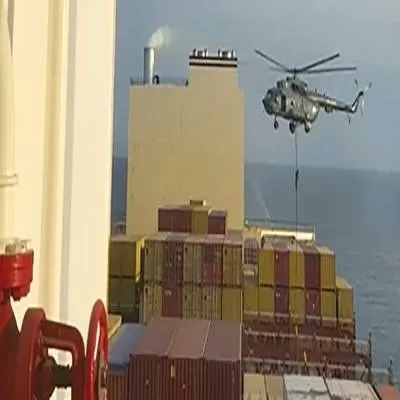

A line-up of over 200 port projects on India’s long coastline is improving the prospects for vendors of port construction equipment. Port projects involve a range of equipment for different purposes. For instance, marine piling equipment, crawler cranes, barges of all kinds, concreting batching plants, and so on. Indeed, demand for all such equipment is gradually marching north.

Cranes and concreting equipment

Crawler cranes play a very important role in the construction of ports. According to Nilesh Bhorkar, National Manager – Sales & Marketing, Kobelco Cranes India Pvt Ltd, “Crawler cranes mounted on barges are an essential part of port construction and demand for these of capacity 80 tonne to 400 tonne is increasing, albeit slowly. It will be a promising segment in the coming years; thus, we are preparing to launch higher capacity cranes. We currently offer 100 tonne crawler cranes but will add 150 tonne and 250 tonne crawler cranes to our fleet in the coming months. Large contractors engaged with port construction as well as heavy industrial infrastructure development such as steel industries, power plants and refineries will be the main takers for higher capacity cranes.”

“We have supplied one batching plant for Pipavav Port,” says Kalpesh Soni, Sr Manager, Marketing, Conmat Systems Ltd. “With Gujarat leading the way in port development projects, we are hopeful of tapping more opportunities in future.”

Niche equipment

Niche equipment used in marine infrastructure development includes various kinds of barges, jack-up platforms, dredgers, etc. While Indian players exist to take care of these needs, some companies are opting to import barges and dredgers at a much higher cost. According to Mohan Lal, Director, Mech Marine, a shipbuilding company based in Mumbai, “Indian shipyards possess the knowhow and technical capabilities to design and construct barges, dredgers, hopper barges, jack-up platforms and pontoons needed for port construction. Afcons, Simplex, Essar Projects, Continental Constructions are a few companies that have availed our services in the past. A few foreign contractors engaged in port construction in India as well as the Middle East are bringing in equipment from Dubai.”

“When imported products like jack-ups are used,” cautions SV Rajadhyaksha, CEO, Leighton Welspun Contractors Pvt Ltd, “it becomes vital to maintain sufficient inventory of spares and train personnel in maintenance.”

Marine piling

Vendors are also seeing a greater off-take of hydraulic rigs and impact hammers used for marine piling, an essential part of port construction activities. “Demand for piling rigs for port projects has been rising since a few years, however the slow pace of execution of these projects and the detailed project planning involved prior to starting has sometimes held back orders that were expected to materialise” says DV Brahme, Regional Manager, Mait India Foundation Equipment Pvt Ltd. “The pace of execution will pick up as land acquisition and clearance hurdles are sorted out. We expect that the collective demand for equipment for many port projects that are coming up simultaneously will increase in the coming months.”

“With more port projects coming up, the requirement for hydraulic impact hammers that can work underwater will rise,” shares Uthpala Suvarna, Director-Operations, Suretech Infrastructure Pvt Ltd. “We offer the IHC Hydrohammer from the IHC Merwede Group of companies. This is a one-of-its-kind double acting impact hammer with underwater capabilities.”

Developing a port is no less than the creating a township and it brings together a wide range of construction equipment capable of working in the sea as well as in the coastal region. So the scope for coastal piling rigs, a close associate of marine piling, is growing too. “Barring a few exceptions, coastal land is soft and marshy with low load-bearing capacity,” explains Brahme. “Pile foundations and stone columns and grouting are amongst the fastest proven ways to improve the load-bearing capacity of such ground.” Bored piling rigs have been extensively used for marine piling at the L&T Shipyard in Katupally, for the NHAI Cochin Port connectivity project, and for the Narmada Bridge in Madhya Pradesh. Essar has used impact hammers for over 50,000 driven cast-in-situ piles for ground improvement along the sea shore at Hariza. And Valecha Engineering Ltd has executed a similar coastal piling at Paradip.

Undoubtedly, as a greater number of port projects get underway, the prospects for equipment vendors are bound to grow more plentiful.

Case Study 1

European marine piling equipment

Purpose: Marine piling

Project: Essar Ports projects, such as Hazira Jetty

User: Essar Ports

Equipment: Bored marine piling brings together a lot of specialised equipment such as hydraulic rotary piling rigs (capacities ranging from 180 kNm to 300 kNm and depth range in excess of 50 m) and hydraulically operated impact hammers for driving sheet piles/casings into the seabed. These hammers are adapted to underwater operations. High-capacity crawler cranes (100 to 250 tonne) are used for impact hammer lifting, load handling, concreting handling, etc. This piling and associated equipment is mounted on marine barges like crane barges, supply barge, jack-up barge, etc.

Reason for choice: “We use European brands of hydraulic piling rigs, impact hammers and high-capacity cranes as India is highly dependent on international manufacturers,” says Pradeep Kathuria, Head & CEO, Essar Equipment Bank, Essar Projects. “As time, cost and quality are essential attributes of a successful project, this speciality equipment introduces a high level of mechanisation that ensures results in optimum time and cost with desired quality. It also helps in pile construction in difficult terrains and conditions. Direct mud circulation, the traditional method of piling using locally available piling winches, is low cost but slower and hence only suitable for lower volumes.”

Usage best practices: “We always insist on original equipment manufacturer (OEM) services,” adds Kathuria. “To get the best OEM services, we usually enter into annual rate contracts (ARCs) with all the major equipment providers. ARCs include uninterrupted spares supply for the ARC periods. Additionally, we also stock essential and desirable spares for periodic maintenance schedules. OEM trained dedicated and highly qualified teams of engineers and technicians take care of specialised services.”

Case Study 2

Reliance on imported dredgers

Purpose: Inner channel dredging with reclamation/outer channel dredging

Project: Dredging at Krishnapatnam Port

User: Navayuga Engineering Company

Equipment: Inner channel dredging using cutter suction dredger with attendant floating pipelines from Daman (Netherlands), IHC (Netherlands) and a third, which is Chinese made. Chinese-made trailer suction hopper dredgers (TSHD) were used for the outer channel dredging.

Reason for choice: “Smaller cutter section dredgers (CSD) and medium-sized dredgers are being made in Indian yards,” says

Dr PV Chandramohan, President-Technical, Navayuga Engineering Company. “We chose to import the cutter suction dredger because large CSDs are not made in India. Outer channel dredging cannot be coupled with reclamation projects as the spoil has to be taken to deeper contours and deposited there. If the hopper size is large, the number of trips to the outer bar can be limited. Trailer suction hopper dredgers aren’t made in India and must be imported. Chinese dredgers are cheaper than those from Europe but require regular maintenance.”

Usage best practices: “As dredging is equipment-oriented work, machine reliability is the key to the timely completion of a project,” adds

Dr Chandramohan. “In-house maintenance capability must be developed. We use a lot of imported machinery but do not depend on the manufacturer alone for service and spares. Our well-equipped maintenance wing looks after repair. Spares are by and large available. Apart from the equipment, knowledge of the sediment to be removed is crucial. Planning the dredging project is important as well. Productivity is the catchword. In a dredger, it is the amount of solids in the dredge mix. Optimising the working of a TSHD to maximise solids involves adjusting operating parameters such as the angle of the drag head and the valve opening to come up with the best combination.”

Case Study 3

Systems to manage spares

Purpose: Construction of various jetties and related developments

Project: Mundra Port

User: PMC Projects India Pvt Ltd

Equipment: Bore piling winch (5/7.5 tonne) with various boring tools (DMC chisel, sludge pump and rotary drilling rig with various special boring tools (18-26 t-m cap) were needed for the foundation work. Superstructure work involved the combination of precast concrete slab/beam and cast in-situ job for which we used a concrete batching plant, concrete transit mixer, concrete pump, boom placer, various types of vibrators, bottom discharge hopper, welding set, power supply generator, mobile and stationary crane, rail-mounted precast erection gantry, etc.

Reason for choice: “We gauge the suitability of the equipment for the proposed construction methodology,” says Ambar Dave, Assistant General Manager, PMC Projects (India) Pvt Ltd. “Time on hand to execute the project also impacts this choice, as do equipment cost and quality. Performance reliability of the equipment manufacturer is factored into this decision as well. Whereas we prefer Indian manufacturers like Metco, Simplex, DE Enterprise, etc, for the bore piling winch and most of the concreting equipment is also from Indian manufacturers. Imported rotary drilling rigs from brands like IMT, Soilmec, Liebherr, MAIT, etc, suit our needs.”

Usage best practices: “Spares and services are vital for the successful execution of construction projects,” adds Dave. “An in-house or external agency is made responsible for the maintenance of company-owned equipment. The executing contractor becomes responsible if the job is fully awarded. Our inventory management system, which is a part of our SAP ERP, helps manage stocks of spares.”

Case Study 4

Crawler crane selection

Purpose: Miscellaneous port construction activities necessitating a crawler crane

User: Simplex Infrastructures

Project: Adani Port

Equipment application: Crawler cranes are one of the few machines that can reach the actual site and are used for the construction of the port/jetty as support equipment for the piling application. These applications include movement of stones at the time of filling by converting the cranes into grabs; sheet piling for the side wall application of the jetty, port and storage areas; placement of stones during the breakwater construction; and for various other utility operations during the construction of port/jetty. However, this depends on its low ground bearing pressure capability and ability to work in unprepared ground conditions. Crawler cranes are also mounted on barges and pontoons for dredging application. These crawler cranes are required to have free fall on their main and auxiliary drums, which is required for dredging, grabbing and piling application.

Reason for choice: “We are using many reputed brand of cranes for our marine works including Fuwa make crawler crane models 35 mt, 50 mt,

75 mt, 80 mt and 150 mt, which have a freefall arrangement on the main and auxiliary drum, and this feature is required for port construction work,” says S Ghosh Dastidar, Technical Director, Simplex Infrastructures Ltd. “The boom, upper structure and swing bearing are specially designed and are made robust for this application.”

Usage best practices: The selection of the crane depends on the few parameters describing the crane applications like the amount of the load to be handled, the height at which the load is to be placed and the distance from the load placing point to the location of the crane (radius of operation). The type of job to be carried out is an important factor as well. The ground condition and mobility requirement decide if a crawler crane or a tire-mounted crane is better suited. The type of job and the available head room, etc, decide if the crane should have a lattice boom or a telescopic boom. Any crane would give the best services if selected as such, depending on the actual use and the site conditions. As working conditions at all marine worksites are generally risky, the crane should have in-built modern safety functions.

To share your views on this feature, write in at feedback@ASAPPmedia.com

While vendors are seeing the demand for a medley of port construction equipment chart an upwards trajectory, users are growing more discerning about their choice of product, finds Charu Bahri.A line-up of over 200 port projects on India’s long coastline is improving the prospects for vendors of port construction equipment. Port projects involve a range of equipment for different purposes. For instance, marine piling equipment, crawler cranes, barges of all kinds, concreting batching plants, and so on. Indeed, demand for all such equipment is gradually marching north.Cranes and concreting equipmentCrawler cranes play a very important role in the construction of ports. According to Nilesh Bhorkar, National Manager – Sales & Marketing, Kobelco Cranes India Pvt Ltd, “Crawler cranes mounted on barges are an essential part of port construction and demand for these of capacity 80 tonne to 400 tonne is increasing, albeit slowly. It will be a promising segment in the coming years; thus, we are preparing to launch higher capacity cranes. We currently offer 100 tonne crawler cranes but will add 150 tonne and 250 tonne crawler cranes to our fleet in the coming months. Large contractors engaged with port construction as well as heavy industrial infrastructure development such as steel industries, power plants and refineries will be the main takers for higher capacity cranes.”“We have supplied one batching plant for Pipavav Port,” says Kalpesh Soni, Sr Manager, Marketing, Conmat Systems Ltd. “With Gujarat leading the way in port development projects, we are hopeful of tapping more opportunities in future.”Niche equipmentNiche equipment used in marine infrastructure development includes various kinds of barges, jack-up platforms, dredgers, etc. While Indian players exist to take care of these needs, some companies are opting to import barges and dredgers at a much higher cost. According to Mohan Lal, Director, Mech Marine, a shipbuilding company based in Mumbai, “Indian shipyards possess the knowhow and technical capabilities to design and construct barges, dredgers, hopper barges, jack-up platforms and pontoons needed for port construction. Afcons, Simplex, Essar Projects, Continental Constructions are a few companies that have availed our services in the past. A few foreign contractors engaged in port construction in India as well as the Middle East are bringing in equipment from Dubai.”“When imported products like jack-ups are used,” cautions SV Rajadhyaksha, CEO, Leighton Welspun Contractors Pvt Ltd, “it becomes vital to maintain sufficient inventory of spares and train personnel in maintenance.”Marine pilingVendors are also seeing a greater off-take of hydraulic rigs and impact hammers used for marine piling, an essential part of port construction activities. “Demand for piling rigs for port projects has been rising since a few years, however the slow pace of execution of these projects and the detailed project planning involved prior to starting has sometimes held back orders that were expected to materialise” says DV Brahme, Regional Manager, Mait India Foundation Equipment Pvt Ltd. “The pace of execution will pick up as land acquisition and clearance hurdles are sorted out. We expect that the collective demand for equipment for many port projects that are coming up simultaneously will increase in the coming months.”“With more port projects coming up, the requirement for hydraulic impact hammers that can work underwater will rise,” shares Uthpala Suvarna, Director-Operations, Suretech Infrastructure Pvt Ltd. “We offer the IHC Hydrohammer from the IHC Merwede Group of companies. This is a one-of-its-kind double acting impact hammer with underwater capabilities.”Developing a port is no less than the creating a township and it brings together a wide range of construction equipment capable of working in the sea as well as in the coastal region. So the scope for coastal piling rigs, a close associate of marine piling, is growing too. “Barring a few exceptions, coastal land is soft and marshy with low load-bearing capacity,” explains Brahme. “Pile foundations and stone columns and grouting are amongst the fastest proven ways to improve the load-bearing capacity of such ground.” Bored piling rigs have been extensively used for marine piling at the L&T Shipyard in Katupally, for the NHAI Cochin Port connectivity project, and for the Narmada Bridge in Madhya Pradesh. Essar has used impact hammers for over 50,000 driven cast-in-situ piles for ground improvement along the sea shore at Hariza. And Valecha Engineering Ltd has executed a similar coastal piling at Paradip.Undoubtedly, as a greater number of port projects get underway, the prospects for equipment vendors are bound to grow more plentiful.Case Study 1European marine piling equipmentPurpose: Marine pilingProject: Essar Ports projects, such as Hazira JettyUser: Essar PortsEquipment: Bored marine piling brings together a lot of specialised equipment such as hydraulic rotary piling rigs (capacities ranging from 180 kNm to 300 kNm and depth range in excess of 50 m) and hydraulically operated impact hammers for driving sheet piles/casings into the seabed. These hammers are adapted to underwater operations. High-capacity crawler cranes (100 to 250 tonne) are used for impact hammer lifting, load handling, concreting handling, etc. This piling and associated equipment is mounted on marine barges like crane barges, supply barge, jack-up barge, etc.Reason for choice: “We use European brands of hydraulic piling rigs, impact hammers and high-capacity cranes as India is highly dependent on international manufacturers,” says Pradeep Kathuria, Head & CEO, Essar Equipment Bank, Essar Projects. “As time, cost and quality are essential attributes of a successful project, this speciality equipment introduces a high level of mechanisation that ensures results in optimum time and cost with desired quality. It also helps in pile construction in difficult terrains and conditions. Direct mud circulation, the traditional method of piling using locally available piling winches, is low cost but slower and hence only suitable for lower volumes.”Usage best practices: “We always insist on original equipment manufacturer (OEM) services,” adds Kathuria. “To get the best OEM services, we usually enter into annual rate contracts (ARCs) with all the major equipment providers. ARCs include uninterrupted spares supply for the ARC periods. Additionally, we also stock essential and desirable spares for periodic maintenance schedules. OEM trained dedicated and highly qualified teams of engineers and technicians take care of specialised services.”Case Study 2Reliance on imported dredgersPurpose: Inner channel dredging with reclamation/outer channel dredgingProject: Dredging at Krishnapatnam Port User: Navayuga Engineering CompanyEquipment: Inner channel dredging using cutter suction dredger with attendant floating pipelines from Daman (Netherlands), IHC (Netherlands) and a third, which is Chinese made. Chinese-made trailer suction hopper dredgers (TSHD) were used for the outer channel dredging.Reason for choice: “Smaller cutter section dredgers (CSD) and medium-sized dredgers are being made in Indian yards,” says Dr PV Chandramohan, President-Technical, Navayuga Engineering Company. “We chose to import the cutter suction dredger because large CSDs are not made in India. Outer channel dredging cannot be coupled with reclamation projects as the spoil has to be taken to deeper contours and deposited there. If the hopper size is large, the number of trips to the outer bar can be limited. Trailer suction hopper dredgers aren’t made in India and must be imported. Chinese dredgers are cheaper than those from Europe but require regular maintenance.” Usage best practices: “As dredging is equipment-oriented work, machine reliability is the key to the timely completion of a project,” adds Dr Chandramohan. “In-house maintenance capability must be developed. We use a lot of imported machinery but do not depend on the manufacturer alone for service and spares. Our well-equipped maintenance wing looks after repair. Spares are by and large available. Apart from the equipment, knowledge of the sediment to be removed is crucial. Planning the dredging project is important as well. Productivity is the catchword. In a dredger, it is the amount of solids in the dredge mix. Optimising the working of a TSHD to maximise solids involves adjusting operating parameters such as the angle of the drag head and the valve opening to come up with the best combination.”Case Study 3Systems to manage sparesPurpose: Construction of various jetties and related developmentsProject: Mundra PortUser: PMC Projects India Pvt LtdEquipment: Bore piling winch (5/7.5 tonne) with various boring tools (DMC chisel, sludge pump and rotary drilling rig with various special boring tools (18-26 t-m cap) were needed for the foundation work. Superstructure work involved the combination of precast concrete slab/beam and cast in-situ job for which we used a concrete batching plant, concrete transit mixer, concrete pump, boom placer, various types of vibrators, bottom discharge hopper, welding set, power supply generator, mobile and stationary crane, rail-mounted precast erection gantry, etc.Reason for choice: “We gauge the suitability of the equipment for the proposed construction methodology,” says Ambar Dave, Assistant General Manager, PMC Projects (India) Pvt Ltd. “Time on hand to execute the project also impacts this choice, as do equipment cost and quality. Performance reliability of the equipment manufacturer is factored into this decision as well. Whereas we prefer Indian manufacturers like Metco, Simplex, DE Enterprise, etc, for the bore piling winch and most of the concreting equipment is also from Indian manufacturers. Imported rotary drilling rigs from brands like IMT, Soilmec, Liebherr, MAIT, etc, suit our needs.”Usage best practices: “Spares and services are vital for the successful execution of construction projects,” adds Dave. “An in-house or external agency is made responsible for the maintenance of company-owned equipment. The executing contractor becomes responsible if the job is fully awarded. Our inventory management system, which is a part of our SAP ERP, helps manage stocks of spares.”Case Study 4Crawler crane selectionPurpose: Miscellaneous port construction activities necessitating a crawler craneUser: Simplex InfrastructuresProject: Adani PortEquipment application: Crawler cranes are one of the few machines that can reach the actual site and are used for the construction of the port/jetty as support equipment for the piling application. These applications include movement of stones at the time of filling by converting the cranes into grabs; sheet piling for the side wall application of the jetty, port and storage areas; placement of stones during the breakwater construction; and for various other utility operations during the construction of port/jetty. However, this depends on its low ground bearing pressure capability and ability to work in unprepared ground conditions. Crawler cranes are also mounted on barges and pontoons for dredging application. These crawler cranes are required to have free fall on their main and auxiliary drums, which is required for dredging, grabbing and piling application.Reason for choice: “We are using many reputed brand of cranes for our marine works including Fuwa make crawler crane models 35 mt, 50 mt, 75 mt, 80 mt and 150 mt, which have a freefall arrangement on the main and auxiliary drum, and this feature is required for port construction work,” says S Ghosh Dastidar, Technical Director, Simplex Infrastructures Ltd. “The boom, upper structure and swing bearing are specially designed and are made robust for this application.”Usage best practices: The selection of the crane depends on the few parameters describing the crane applications like the amount of the load to be handled, the height at which the load is to be placed and the distance from the load placing point to the location of the crane (radius of operation). The type of job to be carried out is an important factor as well. The ground condition and mobility requirement decide if a crawler crane or a tire-mounted crane is better suited. The type of job and the available head room, etc, decide if the crane should have a lattice boom or a telescopic boom. Any crane would give the best services if selected as such, depending on the actual use and the site conditions. As working conditions at all marine worksites are generally risky, the crane should have in-built modern safety functions.To share your views on this feature, write in at feedback@ASAPPmedia.com