- Home

- Real Estate

- Delhi section of the 82-km 14-lane Delhi-Meerut Green Expressway completed in a record 18 months. Here's more!

Delhi section of the 82-km 14-lane Delhi-Meerut Green Expressway completed in a record 18 months. Here's more!

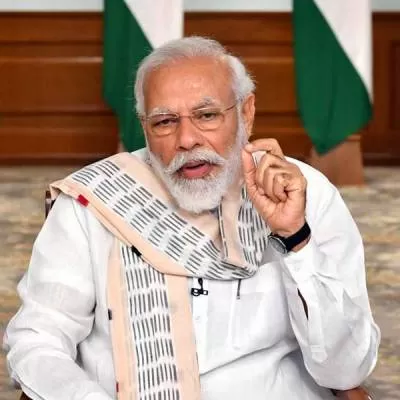

India's much awaited Delhi-Meerut Expressway (Delhi section) was recently inaugurated and dedicated to the nation by Prime Minister Narendra Modi. The project was successfully commissioned by NHAI and Welspun Enterprises in a record time of 18 months as against the scheduled 30 months. This sustainable green expressway is the first project under the hybrid annuity model (HAM), which aims at providing a fast link between Delhi and Meerut.<br /> <br /> <span style="font-weight: bold;">Features and scope of work</span><br /> With a vision to increase commerce by reducing the travel time between cities, decongest traffic jams and reduce pollution, NHAI along with Welspun Enterprises, came up with a blueprint to build a sustainable expressway. The aim was to construct a self-sustaining green expressway that sets a new benchmark for highway infrastructure in the country.<br /> <br /> Welspun Enterprises was awarded with this project in January 2016 under HAM. The 8.716-km-long Section-1 of the Delhi-Meerut Expressway from Nizamuddin Bridge to the Uttar Pradesh border was not only successfully completed but also exceeded all expectations. It consists of a six-lane expressway in the centre, an eight-lane highway (four lanes on each side), five flyovers, one major bridge, two minor bridges, four vehicle underpasses (VUPs) and four foot over-bridges (FOBs). The scope of work also included widening of the existing lanes, dedicated cycle track and pedestrian walkway along both sides, and utility drain and duct. <br /> <br /> <span style="font-weight: bold;">Success parameters </span><br /> Section-I of the Delhi-Meerut Expressway was successfully completed in May 2018 in a record 18 months, ie, 12 months ahead of its schedule - which is in itself a benchmark. <br /> <br /> "The success of any project depends on the synchronisation of various activities such as utility shifting, forest clearance, source identification, resource mobilisation, manpower engagements, location and construction of camp, etc, which were efficiently managed in coordination with NHAI. Meticulous planning and timely follow-up with various government agencies such as BSES, GAIL, IGL, DTL, DJB and independent engineers and various subcontractors ensured smooth execution of this project." says <span style="font-weight: bold;">Sandeep Garg, Managing Director & CEO, Welspun Enterprises.</span><br /> <br /> He further adds, "We are proud to be associated with NHAI under HAM. We are also proud to contribute through industry-first initiatives such as vertical gardens, cycling track, solar lighting and beautification of this stretch. The successful completion of this expressway well ahead of the stipulated time strongly showcases our strength in the infrastructure space. <br /> <br /> Welspun Group, through its technological excellence, has also been contributing to the nation's growth through its various business verticals and is proud to be associated with NHAI to develop various HAM projects."<br /> <br /> <span style="font-weight: bold;">Time-cost balance</span><br /> In any project, there is a possible time-cost balance that leads to its success. "In this project, we were able to achieve this by value engineering to reduce overall construction time as well as taking support of technology such as the use of sacrificial shuttering to save time on shuttering removal and reduce cycle time," shares Garg. "We also used specialised admixtures to reduce the setting time of concrete," he adds. <br /> <br /> While the initial project cost was Rs 8.415 billion, considering the additional cost owing to the change in scope as well as the impact of GST, the overall project cost is estimated at Rs 9.5 billion.<br /> <br /> <span style="font-weight: bold;">The benefits</span><br /> With Section-I of the project commissioned, the travel time has significantly reduced from 45 minutes to just 8 minutes, resulting in tremendous savings in time and fuel consumption. <br /> <br /> This expressway includes a 2.5-m-wide cycle track on either side of the highway, a vertical garden with drip irrigation to reduce the carbon footprint, a solar power plant for clean power, solar lighting system, fountains and replicas of Qutub Minar and Ashoka Sthambh for beautification. About 40,000 trees were transplanted to enhance the environment and the junction is designed so as to retain existing trees. Other benefits include curbing the pollution in Delhi through diversion of traffic to other states like Uttarakhand and Uttar Pradesh, and improving the connectivity of Delhi with two states, which will be a catalyst for improvement in economic activities. Being the business capital, Delhi requires a huge workforce and this project will ease out manpower availability in the region.<br /> <br /> <span style="font-weight: bold;">Unmatched technologies</span><br /> Several technologies and methods were used in the construction of this project. <br /> These include an intelligent compaction system to monitor the quality of compaction; PTZ cameras to analyse progress as well as safety and other quality requirements; and video monitoring and analytical reports to resolve bottlenecks in real time. Also, a design change was initiated to convert the well foundation to pile foundation to reduce construction time of the bridge. Green walls and solar panels have been installed along the major bridge for beautification and to reduce pollution. A solar power plant has been installed to meet all the power requirements of the project, thereby reducing overall power cost and promoting use of clean energy. Moreover, a dedicated QMC was hired to monitor all the activities and raise an alarm in case of any violation in operating standards and methodologies during construction.<br /> <br /> <span style="font-weight: bold;">Fully equipped</span><br /> Cranes of all sizes such as hydra or cranes from 10 tonne to 500 tonne capacity have been used for the construction of this stretch. Also, as Garg tells us, additional cranes were mobilised for launching girders in lesser duration. This reduced construction time and traffic congestion. Further, hydraulic piling rigs were used at all locations to avoid shifting from one location to another. Boom placers were placed separately at all structure locations to speed up concrete pouring. Sensor pavers for bituminous works (BC, DBM and WMM) were separately made available; hence, shifting time was substantially saved. Precast sections were used in various structures to reduce construction time. <br /> <br /> What's more, additional equipment was mobilised at various fronts, enabling work to be continued in parallel at different locations. And, water tankers were in rotation for 24 hours.<br /> <br /> <span style="font-weight: bold;">Quality materials</span><br /> The package has made use of high-quality construction materials, adding to the life and quality of the expressway. High-grade admixtures have been used to achieve early strength of concrete. Geo-composites were used to improve earth slope stability and geosynthetics and geocells were used for soil stabilisation and slope protection. Also, fibre-reinforced concrete was used in crash barriers for improved finish and to reduce shrinkage cracks. Polymer-modified bitumen was used in the wearing course for enhanced texture, better riding quality and increased life of the expressway. What's more, all structures are being painted with anti-carbonation paint, which will protect them against damage from chloride, sulphate and other corrosive salts.<br /> <br /> <span style="font-weight: bold;">World-class safety measures </span><br /> The project has undertaken world-class safety measures for a better commuting experience. <br /> <br /> The number of safe man hours clocked exceeds 34.24 lakh. "During winters, the number of accidents usually increases to a greater extent in Delhi owing to the heavy fog, which results in poor visibility," adds Garg. <br /> <br /> "In this project, LED lights have been used, which also work effectively under fog and provide additional safety for users. LED lighting has been used at three locations for beautification and better aesthetics. Also, anti-fog lights have been used at the major bridge for better visibility. Moreover, CCTV cameras, retro reflective signage, antiglare in the medians and U-turn in all underpasses as well as advanced traffic management system (ATMS) have been installed."<br /> <br /> <span style="font-weight: bold;">Funding and construction challenges</span><br /> Being the first project under the HAM model, there were initial apprehensions about funding. "However, as the project progressed, financial closure was successfully achieved before the stipulated time," reveals Garg. <br /> <br /> Amid the record time the project was completed in, it faced several challenges in construction. To take care of the heavy traffic from Ghaziabad to Ring Road in peak time, permission for traffic management and diversion was taken from relevant authorities. "The project included a complete stretch in urban area on both sides," explains Garg. "Working front and space were big constraints keeping in mind the safety of commuters as the project stretch caters to huge traffic." says Garg. Also, multiple subcontractors and various agencies were engaged at the same time at various locations to efficiently manage planning. Utility shifting involved many agencies such as DJB, BSES, IGL, Army, various telephone and data carriers, etc.<br /> <br /> All considered, constructing India's first 14-lane highway with a designed speed of 120 km per hour while working in the heaviest traffic without any loss of life is indeed commendable. Kudos!<br /> <br /> <span style="font-weight: bold;">Project Details<br /> Total project length:</span> 82 km<br /> <span style="font-weight: bold;">Completed phase:</span> Section 1-Nizamuddin Bridge (km-0.000) to Delhi-Uttar Pradesh Border (km-8.360) of NH-24.<br /> <span style="font-weight: bold;">Type:</span> Expressway based on HAM.<br /> <span style="font-weight: bold;">Completion date:</span> May 27, 2018.<br /> <span style="font-weight: bold;">Total cost:</span> Rs.9.5 billion.<br /> <span style="font-weight: bold;">Design consultant:</span> STUP Consultants. <br /> <span style="font-weight: bold;">Website:</span> www.stupco.com; <br /> B&S Engineering Consultants. <br /> <span style="font-weight: bold;">Website:</span> www.bsecpl.in; <br /> AECOM India. <br /> <span style="font-weight: bold;">Website: </span>www.aecom.com/in; <br /> G Engineering Services. <br /> <span style="font-weight: bold;">Website: </span>www.g-eng.in; A&T Engineering; <br /> Khanna Designers & Consultants. <br /> <span style="font-weight: bold;">Website:</span> www.khannadesigners.com<br /> <span style="font-weight: bold;">Project consultant:</span> Independent engineer; NHAI consultant - SAI Consulting Engineers. <br /> <span style="font-weight: bold;">Website:</span> www.saiindia.com<br /> <span style="font-weight: bold;">Construction contractor: </span>Welspun Delhi Meerut Expressway. <br /> <span style="font-weight: bold;">Website:</span> www.welspunenterprises.com<br /> <span style="font-weight: bold;">Type of equipment used:</span> Hydra or cranes from 10 tonne to 500 tonne capacity, hydraulic piling rigs, intelligent compaction system and PTZ cameras to analyse progress among others.<br /> <span style="font-weight: bold;">Materials used: </span>High-grade admixtures, geo-composites, geosynthetics, geocells, fibre-reinforced concrete and polymer-modified bitumen, among others.<br /> <br /> <span style="font-weight: bold;">- SERAPHINA D'SOUZA</span><br />