Globally, the material handling equipment market is projected to grow at 5.4 per cent between now and 2030. In particular, India and China are expected to help OEMs expand their end-user markets, possibly because this segment of machines is permeating so many varied industries, from ports to the construction of buildings and infrastructure, the maintenance of those assets, logistics and more.

What does it take for harbour mobile cranes to handle heavy cargo loads?

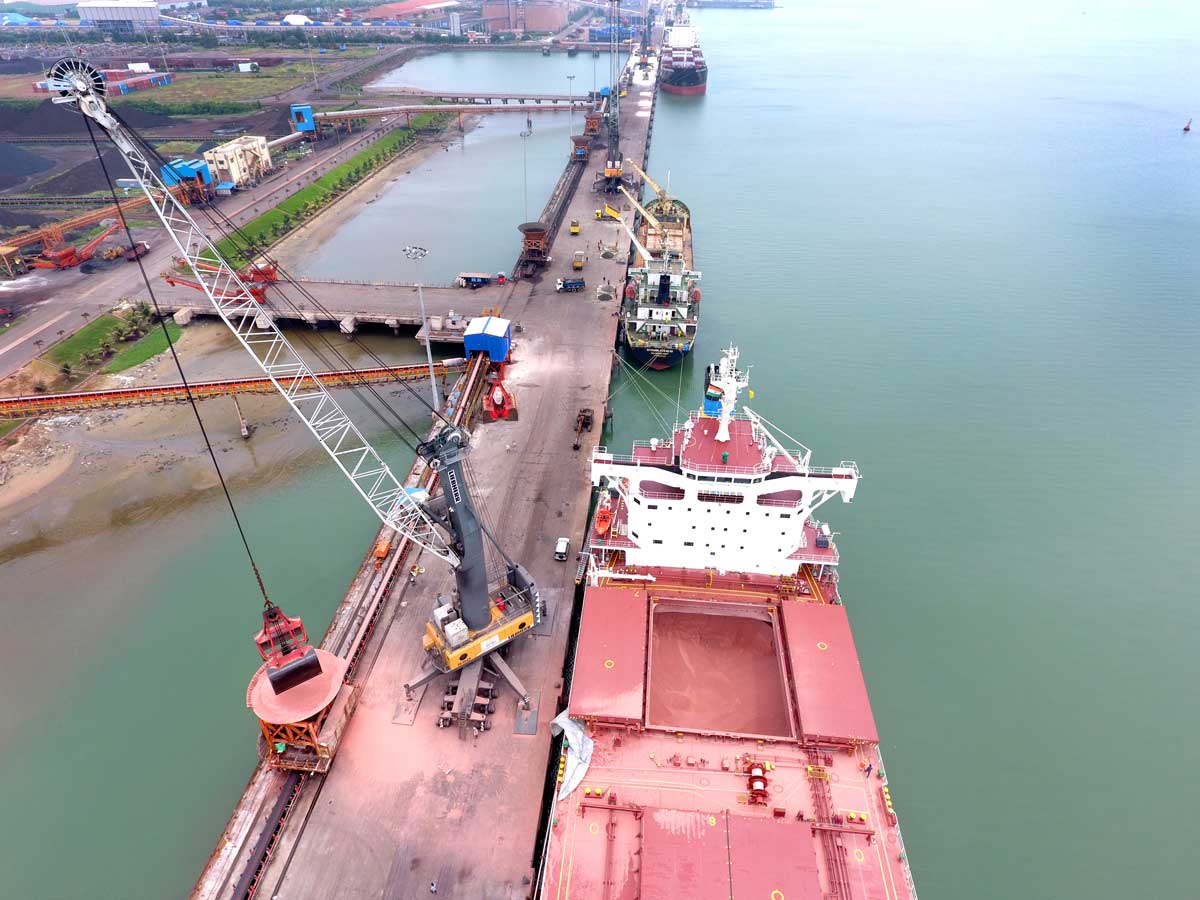

The Bothra Group has been using Liebherr harbour mobile cranes since 2004. “As of today, we have the second largest fleet (after Adani) of harbour mobile cranes in India—17 Liebherr cranes across the east coast ports where we have operations, such as Haldia, Paradip, Visakhapatnam, Gopalpur and Kakinada,” shares Rahil Sahu, General Manager, Bothra Shipping Services. “While purchasing a crane, we consider the traffic forecast along with ship sizes expected, operating capacity of the machine, capital cost, reliability and availability of [after-sales] service in India. We opted for Liebherr cranes because the brand has a proven track record, provides reliable service and spares are available.”

“One of our learnings through COVID-19 has been the need to become as independent as possible in maintaining a fleet of cranes, especially the sourcing of spares,”he continues.

“For all port and terminal operators, sourcing spares during the pandemic has been a challenge owing to our reliance on foreign machinery. Additionally, with the war in Ukraine, the supply chains of European parts manufacturers continue to be disrupted, affecting operations in Indian ports. In future, all port operators will begin to look for cranes with spares and maintenance needs that can be fulfilled locally instead of relying on imports. This will boost the Government’s Atmanirbhar Bharat policy. In the last year we have actually developed some indigenous components for our own cranes. At present, Indian ports are dependent heavily on imported machinery for their operations. There is an urgent need to develop domestic solutions to be able to grow at a faster rate.”

“We employ 250 people to operate and maintain our fleet of mobile harbour cranes,” shares Sahu. “In collaboration with Liebherr, we have invested in a simulator to train our crane operators so that an operator is well trained and familiar before starting work at site. We’re the only private port operator with a simulator. Appropriate training helps crane operators operate the crane and ensure the productivity and longevity of the machine. In Paradip, our mobile harbour crane ranks second highest in cargo handled annually. In Haldia, our crane ranks the highest. We lay emphasis upon the proper maintenance and operations of the cranes to provide greater output in operations. Training and predictive maintenance have also helped us ensure that our cranes see fewer breakdowns among our competitors. We focus on improving our crane availability where we target each crane to be available for operations for more than 5,000 hours a year. Longer operative hours help the ports to maintain good operating parameters and help reduce costs.”

Why are most Indian rail contractors still using semi-mechanised working methods?

e2ERail has been using track-handling machines since 2010 to load,unload and lay rails and sleepers; screen ballasts; for link work;packing and alignment of rails and for the

replacement and rehab of tracks.

“When choosing equipment, we looked for well-established brands withthe ability to supply quickly, offering a decent credit period andwhose products had a good resale value,” says Sourajit Mukherjee, CEO, e2ERail. “From the perspective of productivity, we look foruser-friendly machines needing no specific onsite training for theoperator and no extra safety parameters, which are compact and easy toshift, economical, fuel-efficient, sound, which save the most manualexecution hours and can be used by smaller teams when our entire workforce isn’t available.”

Deploying hydras for rail work is a semi-mechanised workingmethodology. Mukherjee is keen to reduce the number of workers onsiteto cut down on the vigilant safety measures needed. However,semi-mechanised machines are still far from the most productive way of working.

The best alternative way of working is the newly introduced new trackconstruction (NTC) machines, according to Mukherjee. “NTCs can lay 1,500 m of track (sleepers and rails) every day (in eight hours of workingtime) versus hydras that can manage only about 100 m a day. It’s just thatNTCs are only viable for extensive stretches of tracks, projects thatare upwards of 500 km.Thousands of rail contractors across India have adopted manual andsemi-mechanised construction methods owing to budgetary constraints andoverall logistics and feasibility, whereas only a handful of railcontractors use the NTC machine that costs Rs 25-30 crore. NTCsadditionally require specially designed wagons and depots for operations.”

“We’d like to scale up to fully mechanised working methods but atpresent the cost of the machine enabling such operations isprohibitive,” he adds.

Why are material handling machines vital for the extraction of coal?

In the Singareni Collieries (SCCL) Vakilpali Mine, a feeder breaker helps crush coal underground in the panel itself. The feeder breaker is the last and most important part of Komatsu’s continuous miner equipment package for the extraction of coal from below ground. It is a highly mobile crushing solution that accepts the output of mining and crushes it to make it more amenable for onward haulage. By being placed near the working face and effectively interfaced with onward haulage equipment, the feeder breaker helps both the mining system and the haulage system to operate efficiently and productively.

“With the feeder breaker, crushing happens at a regulated pace, thereby ensuring that coal can be evacuated smoothly from under the ground to the surface through a series of gate belt and trunk belt conveyors,” explains Paka Ravi Kiran, Manager, SCCL Colliery Manager.

“Essentially, the feeder breaker performance is optimised to discharge coal in synchronisation with the rated peak capacity of the belt conveyors, while ensuring minimal downtime. This ensures overall productivity.”

Using a feeder breaker underground helps get the coal to a predetermined size as per the requirement of end-users such as thermal power plants, continues Kiran. “We don’t need to additionally crush the coal at the surface level.”

“It was important that the feeder breaker deliver the desired output size— (-) 100mm or (-) 200mm —and achieve a throughput of 600 tonne per hour,” says Kiran. “A crawler-mounted system would be able to navigate the underground terrain. We also wanted the feeder breaker to be fitted with safety technologies such as an audio-visual alarm, dust suppression system, e-stop, conveyor belt interlock, fire suppression system and area lighting. The machine should be approved by the Directorate General of Mines Safety.”

Why does India’s most iconic bridge need a platform to hold (men and) materials?

The Maharashtra State Road Development Corporation is using an Alimak MC 650 work platform to assist the maintenance of the bridge pylons of Mumbai’s Rajiv Gandhi Sea Link, popularly known as the Bandra Worli Sea Link, India’s fourth longest bridge.

This complex application requires the MC 650 platform to run on a pylon with two inclinations. At every height, the platform must be kept at the zero level.The Alimak unit must also cover the entire circumference of the pylon, and hence adjust to the narrowing circumference as it runs upward. Additionally, a unique Alimak lift installed in the straight vertical shaft with an entrance fitted in the floor of the car (a manhole type entry) has been provided with additional jigs and fixtures to hold hydraulic tensioners to tension the cable of the stayed bridge.

“Alimak offers sturdy, reliable and user-friendly machines, and the model that was chosen met the complexity of this project,” says ShubhasBorse, Executive Engineer, MSRDC, RGSL Toll Maintenance Unit. “While Alimak is little [more than] expensive than other international brands, it offers better safety features and is more reliable in terms of offering technology that has been proven across the globe over seven decades.”

Alimak offers an energy-efficient drive unit, reduced power consumption and a variable frequency control unit, which help reduce the ownership cost of the hoist over its long life.

Which material handling solutions increase human productivity in an e-commerce warehouse?

Ecom Express uses a semi-automated spiral chute and controlled vertical reciprocating conveyors that are capable of simultaneously handling different products from the verticals it serves: firms in the B2B, B2C and e-grocery segments. “To pick up items from the inventory and move them out to the drop zone for invoicing smoothly and conveniently, we deploy multi-bin pick trolleys and platform trolleys,” says Lakshmanan S, Chief Operating Officer, EcomFulfillment Services. “To move heavy material from point to point on the floor, we use platform trolleys and hand pallet trucks. To load and unload trucks, we rely on manual and battery-operated hand pallet trucks.”

Ecom Express’s focus has been on increasing movement yield and safety and, to this end, it has considered grocery-specific handling equipment from reliable, cost-effective brands that offers free mobility on the floor and adheres to proper design ergonomics. “Material handling equipment consistently increases human productivity by minimising the effort required to carry loads,” adds Lakshmanan. “We have the highest regard for quality and delivery speed, crucial factors in logistics where consumer demands are constantly changing.”

While Ecom Express has found the best material handling solution for its requirements, the company reckons that smart conveying could be the next best alternative to what it has developed. “This is because we service such a large multi-tier inventory ecosystem,” explains Lakshmanan.