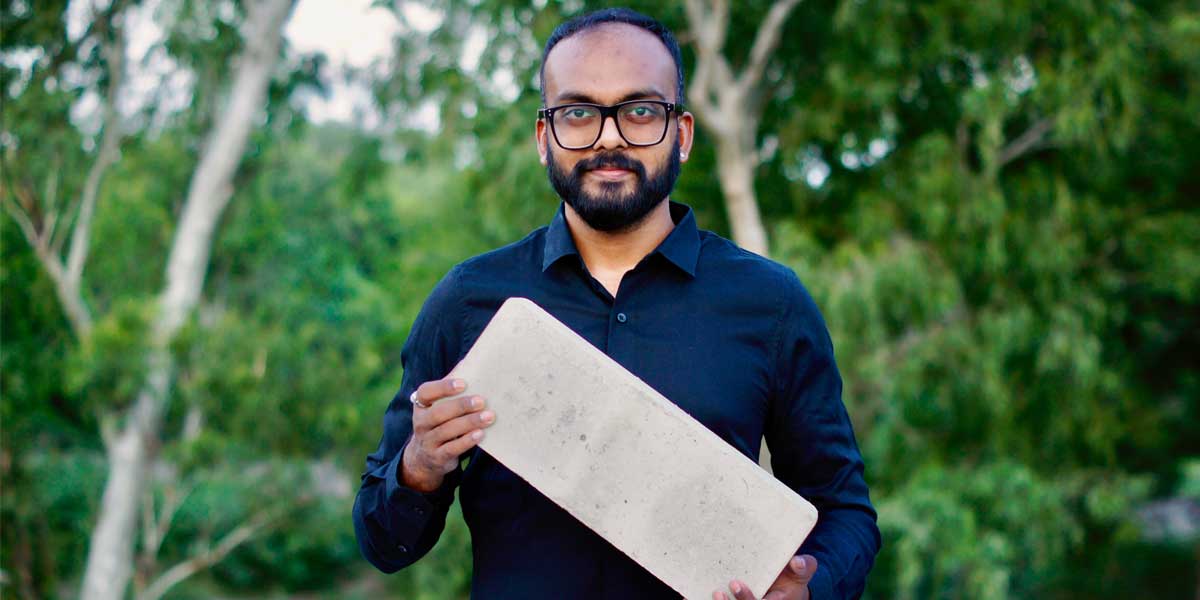

GreenJams is pioneering the use of crop residues to create a low-cost replacement of building materials to cut down on construction costs and improve the building energy efficiency. Tarun Jami, the Founder of GreenJams claims that his product BINDR will help cement companies to cut their carbon footprint by more than 80% when compared to regular Portland cement.

‘Green’ and ‘environmentally efficient’ products have become the buzzwords today. The Indian cement and construction industry is working effectively towards reducing carbon footprints and meeting sustainability targets. Calcination and clinker-making process are the biggest contributors to CO2 emission. About 7-8% of global carbon emissions come from clinker manufacturing alone. Materials like fly ash bricks, AAC blocks, and any other novel building materials use clinker-based cement.

What is clinker? In simple words, raw materials like limestone and clay are crushed and mixed with iron ore or ash and put into cylindrical containers -- kilns at around 1,450 degrees Celsius. This process is called calcination and when the mixture is split into calcium oxide and CO2, it gives a new product called clinker.

GreenJams have changed the way building materials are being manufactured. The company has come up with innovative carbon-negative building materials made of crop residues and industrial by-products. Its product called BINDR is a 100% upcycled product, that can help cement companies cut their carbon footprint by more than 80% when compared to regular Portland cement.

Below are excerpts from the interview with Tarun Jami, the Founder of GreenJams.

How did you start your journey towards making a carbon-neutral building material for the construction industry?

Late during my undergrad days of studying civil engineering, I had come across the topic-what climate change is and the impact that construction activities have on it. Since then, I got conscious of what destruction construction would cause to our environment. Ever since I developed this conviction, I was on the lookout for technologies and materials that would help make construction less harmful to the environment. Towards the end of my engineering, I had stumbled upon a building material called hempcrete. It was carbon-negative and was made of hemp, and it felt like I had discovered a wonderland. I suddenly realised that with this hempcrete, we could make construction better for the planet. Can you imagine that construction could help reverse climate change? That epiphany set me on a journey that took me this far.

Could you brief us about your innovative product BINDR-- a low-carbon replacement of Portland cement? Does it qualify for all quality and strength tests? How is it better than Portland cement?

BINDR is a 100% up-cycled replacement of Portland cement with a characteristic strength equivalent to 43 grade OPC. We aren’t yet claiming structural capabilities for BINDR since we haven’t yet proven its long-term durability. Being a 100% upcycled product, we can cut its carbon footprint by more than 80% when compared to regular Portland cement. At 0.1 kg.CO2/kg, the embodied carbon can’t go lower than this at this price point.

Agrocrete is made from crop residue. You have changed the traditional processes. How did you think of such an innovative idea? How was the response in the market in the beginning?

Agrocrete came out of a lot of trials and tribulations. It emerged as a response to a much deeper societal problem in India. About 44% of Delhi-NCR’s poor winter air quality is because of crop residue burning. Almost 100 million tons of crop residues are burnt annually in India, leading to almost 2 lakh crores of economic loss to the country. I almost crashed my car on my visit to Delhi in late 2019 because of the impact that poor air quality had on my health. While Agrocrete is a scientific anomaly, the most amazing aspect about it is the fact that it augments farmers’ income, keeps the air clean, and generates rural employment. It is carbon-negative and helps reverse climate change too. In the beginning, the market response was very skeptical and it still is. I get questions on fire resistance, decay, and durability of the blocks, which are all great, by the way.

Were there any hurdles you faced? How did you overcome them?

There were so many hurdles we faced. The biggest hurdles were technical and financial. While we somehow managed to solve the financial hurdles, the technical ones were more difficult to overcome. I spent 5 years studying hempcrete academically to equip myself with the technical skills to create Agrocrete. In 2017 I had started my Ph.D. at CSIR-Central Building Research Institute (CSIR-CBRI), Roorkee.

How cost-effective is your Agrocrete product? Does it offer faster completion of a project? How? Could you tell us about the manufacturing process of Agrocrete material? What kind of technology was involved?

Agrocrete helps reduce the cost of construction by almost 50% in comparison to red bricks. The larger block sizes enabled by the significantly lesser weight help make it easy to work with for the masons. We are able to reduce the mortar joints by more than 60% and the plaster requirements by almost 50% because of the cleaner finish. The construction speed is up by almost 2.5X. Agrocrete manufacturing is a completely zero-emissions process. We utilise a patent-pending advanced alkali activation chemical technology. We do not use any furnaces and use latent chemical reactions to achieve strength.

Calcination and clinker-making process are the biggest contributors to CO2 emission. Please share your thoughts on how you can make a difference in this space.

About 7-8% of global carbon emissions come from clinker manufacturing alone. Any reduction in clinker production is beneficial for the planet and humankind. Also, fly ash bricks, AAC blocks, and any other novel building materials use clinker-based cement which contribute a significant sum to the products’ embodied carbon. BINDR could potentially be used to make all these products. Furthermore, by making mortars for block work and plastering, we can reduce the carbon footprint of buildings.

Tell us about the office space that you converted into a manufacturing unit at Roorkee

We built our manufacturing unit from scratch in Roorkee. We built this 1100 sq. ft. industrial building in 4 days flat at a cost of only Rs. 200 /sq. ft. We were able to capture a total of 3.1 tons of carbon dioxide, making it carbon negative. We were able to achieve a 30 percent lesser cost of construction as compared to red bricks by reducing the mortar joints and construction time by 60%. Our Roorkee manufacturing facility was built at Rs. 2 lakhs which would have otherwise cost about Rs. 5 lakhs if we had built it using red bricks. We were able to reduce the mortar joints by more than 60% and increased construction pace by 2.5x and consequently reduced labour costs.

Could you tell us about the ongoing projects and the cost and material involved in it? Any business expansion plans?

We are currently working on supplying Agrocrete hollow and solid blocks and BINDR to multiple residential projects in Punjab, Haryana, Uttarakhand, Delhi-NCR, and Uttar Pradesh. These are individual residences being built by private clients for themselves and the total number of Agrocrete hollow and solid blocks we are supplying are almost 100,000 units and BINDR will be about 200 bags.

We are currently in the process of setting up a brand new 2000 blocks per day manufacturing facility in Visakhapatnam, Andhra Pradesh. The facility is expected to be operational in the next 2-3 months. We have received an overwhelming number of enquiries since 13th July 2021 from Karnataka, Maharashtra and Telangana and are looking for franchising partners who could set up the Agrocrete blocks manufacturing facilities in these markets.

A lot of well-established brands claim to be ‘green’ and ‘environmentally efficient’. Your thoughts on this? Do you think the Indian cement & construction industry is on the right path towards sustainability?

The problem with the industry is that the benchmarks for “green” are getting higher and higher. Also, many products are greenwashed and do not consider lifecycle environmental impacts. With greenwashing becoming rampant, consumers and competitors are going to ask more difficult questions that manufacturers will have to be ready for. The Indian cement industry specifically is one of the greenest in the world. The average embodied carbon of Indian cement is much lower than the global average. With many companies committing to becoming carbon-neutral or even carbon-negative, I think we are on the right path towards sustainability. But it’s also time to now shift focus towards biodiversity and similar pursuits.

What are your plans in terms of adding more to product portfolio, investments, research, and development?

We have always been focused on research and development. Our team is capable, fast, and enterprising enough to develop new products that satisfy customer demands. In fact, our Agrocrete Plaster was created in response to a customer’s request. We are also looking to launch a range of carbon-negative home décor products under a new brand name called Sanscrete. It could potentially be the world’s first carbon-negative home décor brand. Sanscrete will focus on objects for home décor, and corporate and wedding gifting. We are currently looking to raise our first seed round and are inviting angel investors and HNIs to come to speak to us.