- Home

- Building Material

- Concrete

- The Successful Metro Ride

The Successful Metro Ride

The Noida-Greater Noida Metro link has witnessed the fastest-ever pace of infrastructure implementation in India, where a record speed of construction and precasting was a prerequisite.

Atlas Copco is proud to be part of this prestigious project by partnering with CEC International Corporation. With a total project cost of over Rs 5,000 crore, where 30 km with over 1,450 pillars and 18 metro stations are to be erected in a record time of two years, this 30 km elevated metro project is divided into three phases, with CEC International Corporation awarded all three in 2015.

Breaking records

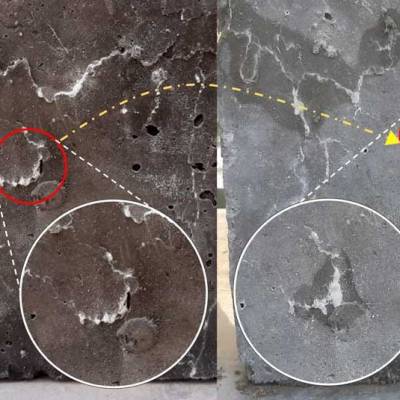

Atlas Copco has been supplying machines from its construction equipment range for metro and railway projects for more than 10 years now. In 2014, the Lucknow Metro Rail Corporation (LMRC) launched one of the most prominent and expensive public transport projects at Rs 12,500 crore (US$ 2 billion), in Uttar Pradesh. Atlas Copco concrete range of products, which included External Concrete Vibrators and AX range of Concrete Vibrators, successfully contributed in making the single largest cast for this project, where six U-Girders were casted in one go, each weighing 145 tonne and 27 m in length. This amounted to a total length of 162 m of U-Girder and a total concrete weight of 870 MT, making it the single largest cast in the metro history of India.

Additionally, the company has been supplying a good number of petrol-driven breakers to the Railways for tie tamping application. Its complete concrete vibration equipment range has been used for various Delhi Metro Projects, where it has ensured machine uptime and on time service, including preventive maintenance of the equipment. Equipment supplied include External Vibrators, Internal Concrete Vibrators High Frequency Type, Plate Compactors, Double Drum Rollers and Jack Hammers.

Metro focus

The company has given prime focus to metro projects, as it can provide solutions to contractors or users from the starting to the finishing stage of a metro construction project. Overall, it has been extremely successful in similar jobs and has expanded its reach across India for larger metro projects.

For the Noida metro project, ER407B (External Vibrators) and AX+SMART high frequency vibrators from Atlas Copco´s concrete range have been used to cast the girders, which require the highest quality equipment with high reliability. Every business opportunity is important for the company, but it takes pride in being a partner in projects of national importance like metros and railways as these projects demand stringent equipment standards and are time driven, for which quality equipment is a must.

The success factor

As the Noida metro was pitched to be the fastest metro construction, hence the customer appreciated that they could not afford any downtime with concrete equipment. To ensure continuous uptime, Atlas Copco deputed a dedicated a service engineer on site. While promoting the ´Make in India´ platform, it has been able to offer customised solutions to the customer through its local state-of-the-art manufacturing plant in Nashik, India, only for supporting these metro projects. Overall, high product reliability and after-sales support have contributed in making this project a great success.

Atlas Copco was able to convince the customer on the importance of quality products for such important and time-bound projects.

Chris Reeves, Project Director, CEC International Corporation, observed, ´We have not experienced any downtime with Atlas Copco External Vibrators as yet, and hence, we have been able to cast girders in a record time. The quality and finish achieved using Atlas Copco External Vibrators has been world-class´.

(Communication by the management of the company)

Atlas Copco has delivered a customised rental solution for on-site nitrogen generation for the Noida Metro project. The Noida-Greater Noida Metro link has witnessed the fastest-ever pace of infrastructure implementation in India, where a record speed of construction and precasting was a prerequisite. Atlas Copco is proud to be part of this prestigious project by partnering with CEC International Corporation. With a total project cost of over Rs 5,000 crore, where 30 km with over 1,450 pillars and 18 metro stations are to be erected in a record time of two years, this 30 km elevated metro project is divided into three phases, with CEC International Corporation awarded all three in 2015. Breaking records Atlas Copco has been supplying machines from its construction equipment range for metro and railway projects for more than 10 years now. In 2014, the Lucknow Metro Rail Corporation (LMRC) launched one of the most prominent and expensive public transport projects at Rs 12,500 crore (US$ 2 billion), in Uttar Pradesh. Atlas Copco concrete range of products, which included External Concrete Vibrators and AX range of Concrete Vibrators, successfully contributed in making the single largest cast for this project, where six U-Girders were casted in one go, each weighing 145 tonne and 27 m in length. This amounted to a total length of 162 m of U-Girder and a total concrete weight of 870 MT, making it the single largest cast in the metro history of India. Additionally, the company has been supplying a good number of petrol-driven breakers to the Railways for tie tamping application. Its complete concrete vibration equipment range has been used for various Delhi Metro Projects, where it has ensured machine uptime and on time service, including preventive maintenance of the equipment. Equipment supplied include External Vibrators, Internal Concrete Vibrators High Frequency Type, Plate Compactors, Double Drum Rollers and Jack Hammers. Metro focus The company has given prime focus to metro projects, as it can provide solutions to contractors or users from the starting to the finishing stage of a metro construction project. Overall, it has been extremely successful in similar jobs and has expanded its reach across India for larger metro projects. For the Noida metro project, ER407B (External Vibrators) and AX+SMART high frequency vibrators from Atlas Copco´s concrete range have been used to cast the girders, which require the highest quality equipment with high reliability. Every business opportunity is important for the company, but it takes pride in being a partner in projects of national importance like metros and railways as these projects demand stringent equipment standards and are time driven, for which quality equipment is a must. The success factor As the Noida metro was pitched to be the fastest metro construction, hence the customer appreciated that they could not afford any downtime with concrete equipment. To ensure continuous uptime, Atlas Copco deputed a dedicated a service engineer on site. While promoting the ´Make in India´ platform, it has been able to offer customised solutions to the customer through its local state-of-the-art manufacturing plant in Nashik, India, only for supporting these metro projects. Overall, high product reliability and after-sales support have contributed in making this project a great success. Atlas Copco was able to convince the customer on the importance of quality products for such important and time-bound projects. Chris Reeves, Project Director, CEC International Corporation, observed, ´We have not experienced any downtime with Atlas Copco External Vibrators as yet, and hence, we have been able to cast girders in a record time. The quality and finish achieved using Atlas Copco External Vibrators has been world-class´. (Communication by the management of the company)