DLF Launches Luxury Project in Gurugram

DLF, India's leading real estate developer, has unveiled an ambitious luxury housing project in Gurugram, valued at ?2.5 billion. Located in Sectors 76 and 77, the DLF Privana project spans over 116 acres and includes high-rise apartments offering spectacular views of the Aravalli Range.

The latest phase, DLF Privana West, features 795 luxury apartments which sold out within three days of launch, generating around ?550 million. This follows the success of DLF Privana South, which sold 1,113 units for approximately ?720 million earlier in the year. These developments highlight the stron..

Migsun Group Plans Rs 5 Bn Investment in Greater Noida Projects

Migsun Group, a prominent real estate developer, has unveiled plans to invest Rs 500 crore in four new projects located in Greater Noida. This initiative is part of the company's strategic efforts to enhance its presence and contribute to the burgeoning real estate sector in the region.

The investment will be directed towards the development of residential and commercial properties, aimed at meeting the increasing demand for quality real estate in Greater Noida. These projects are expected to not only expand Migsun Group's portfolio but also generate employment opportunities and stimul..

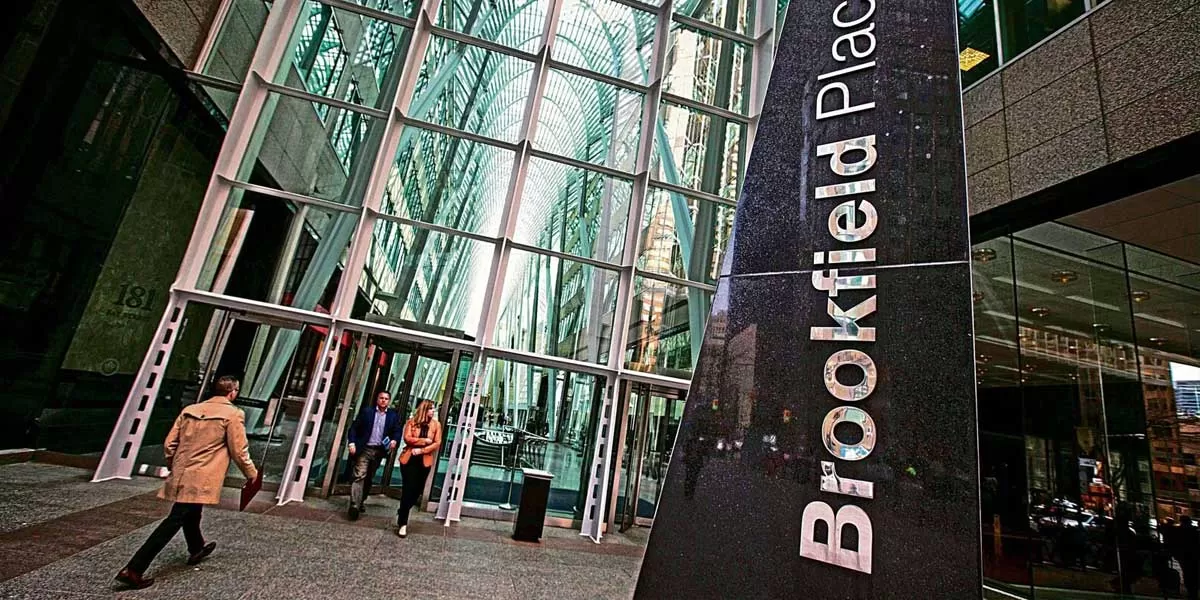

Brookfield India REIT to Acquire Bharti's 50% Stake in Realty JV

Brookfield India REIT is on the verge of purchasing Bharti Enterprises' nearly 50% stake in their joint venture, which focuses on real estate development. This move underscores Brookfield's commitment to expanding its presence in India's dynamic property market. The transaction is expected to be valued at around ?5,000 crore, making it one of the notable deals in the sector.

This acquisition aligns with Brookfield's strategy of enhancing its portfolio with quality assets, leveraging its expertise in real estate management. The deal signifies a significant milestone for both parties, w..