- Home

- Building Material

- Concrete

- The Next Smart Building Material

The Next Smart Building Material

The use of alkali materials and alumino-silicates to form cement is broadly referred to as 'geopolymer' technology, but is also known as alkali-activated cement and inorganic polymer concrete in various parts of the world. In 1978, French materials scientist Dr Joseph Davidovits first coined the term ´geopolymer´, stating ´Raw materials used in the synthesis of silicon-based polymers are mainly rock-forming minerals of geological origin, hence the name geopolymer.´ Geopolymer technology provides comparable performance to traditional cementitious binders, but with an added advantage of significantly reduced greenhouse emissions, increased fire and chemical resistance and waste utilisation. Dr Karthikeyan Jayakumar, Assistant Professor, Department of Civil Engineering, NIT-Trichy, a PhD in structural engineering from IIT-Roorkee, with an ME (structural engineering) and BE (civil engineering), shares more on the material and its advantages.

Application in building, construction and infrastructure: Some of the properties of geopolymer concrete (GPC) are fire-resistance, low drying shrinkage, high early strength and toxic material encapsulation. Owing to these properties, geopolymer concrete has various applications in construction, including pavement bricks, precast beams, fire-resisting composite walls, retaining walls, and radioactive and toxic waste encapsulation.

Supporting materials and manufacturing process: In a study, materials used to manufacture lightweight geopolymer concrete (LWGPC) included fly-ash and ground granulated blast-furnace slag (GGBFS) as binders, fly-ash pellets as coarse aggregates, bottom ash as fine aggregates, sodium hydroxide and sodium silicate as binder agent and super plasticiser.

Preparation of fly-ash aggregates by pelletisation: Pelletisation is the process of consolidating finer moisturised particles into a larger solid material without application of external force. The pellets formed, attain sufficient strength by the force generated inside the mixer.

The aggregates are produced by using ´drum pelletiser´. The efficiency of the pelletisation depends on the angle of orientation and speed of the drum. A tilt of 36oand a rotational speed of 200 rpm were adopted for pelletising. Blade orientation, angle of tilt, the rotational speed of the pelletiser and the pellet formation are shown in (Figure 1, Figure 2, Figure 3 and Figure 4), respectively. After the pelletisation, these aggregates are to be cured. Here, chemical curing is adopted using 8M NaOH solution (Figure 5). The aggregates are dipped into the solution and kept for seven days. After seven days, the aggregates are left to dry in ambient atmosphere.

Preparation of alkaline solution: Sodium hydroxide pellets and sodium silicate solution were mixed to obtain alkaline activator solution. As a reaction creates hot fumes, it takes a day for the solution to cool down. So, the solution should be mixed one day prior to casting. The ratio to be kept for NaOH by Na2SiO3 is 2.5. The specific gravity of the solution can be calculated by 1.49.

Mix proportion: The final mix proportion for cubic metre volume sample:

- Weight of fly-ash aggregate: 851.972 kg.

- Weight of bottom ash: 568.16 kg.

- Weight of fly-ash: 308.46 kg.

- Weight of GGBFS: 132.2 kg.

- Weight of NaOH: 44.07 kg.

- Weight of Na2SiO3 : 110.16 kg.

- Weight of alkaline solution: 154.23 kg.

- Weight of superplasticiser: 6.6099 kg.

- Extra water to be added: 22.033 kg.

How does it work? Geopolymer, an amorphous material (at room temperature), consists of a polymeric Si-O-Al framework, similar to that of zeolites, which is a crystalline material. Applications with geopolymer cements and concretes lead to the introduction of user-friendly systems, as it has been noticed that the manufacture of geopolymer cements emits 80-90 per cent less CO2 (greenhouse effect gas) than Portland cement. According to TF Yen, ´a geopolymer is essentially a mineral chemical compound or mixture of compounds consisting of repeating units; for example, silicon-oxide (-Si-O-Si-O-), silicon-aluminate (-Si-O-Al-O-), ferro-silicon-aluminate (-Fe-O-Si-O-Al-O-) or alumino-phosphate (-Al-O-P-O-), created through a process of geopolymerisation.´

Advantages in the Indian scenario: According to the Ministry of Environment and Forests (MoEF), India produced 163.56 million tonne of fly-ash in 2012-13. Table 1 below shows thermal power generation, coal consumption and ash generation in India for the past two decades. Geopolymer concrete has a wide scope of implementation in future scenarios. It is prepared from natural material rich in silica and alumina. It can utilise a lot of waste material as 95-98 per cent of it is fly-ash alone, which is a unique way of disposing waste material. LWGPC will reduce the dead load of the structure. Geopolymer has low heat of hydration and less setting time. It has great resistance to heat and chemical exposures. These are some of the properties of GPC for which it can gain popularity as a smart building material.

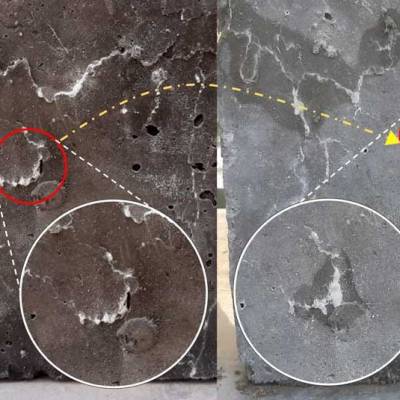

Shortcomings in usage: The shortcoming occured when the geopolymer concrete was prepared using Rice husk ash pellets. The bonding between the geopolymer matrix with Ricehusk ash pellets was very poor.The seven days compressive strength of the LWGPC was found to be 1.44 MPa, which is 94 per cent less than that of control mix (27MPa), as shown in Figures 8 and 9.

The seven days´ compressive strength of the LWGPC was found to be 1.44 MPa, which is 94 per cent less than that of control mix (27 MPa). The reduction in the compressive strength is owing to the alkali-silica reaction (ASR). The ASR is a reaction that occurs over time in concrete between the highly alkaline cement paste and reactive non-crystalline (amorphous) silica, which is found in many common aggregates. This reaction causes the expansion of the altered aggregate by the formation of a swelling gel of calcium silicate hydrate (C-S-H). This gel increases in volume with water and exerts expansive pressure inside the material, causing spalling and loss of strength of the concrete, finally leading to its failure. The mechanisms of ASR are as follows:

The alkaline solution attacks the siliceous aggregate, converting it to viscous alkali silicate gel.

Consumption of alkali by the reaction induces the dissolution of Ca2+ ions into the cement pore water. Calcium ions then react with the gel to convert it to hard C-S-H. The penetrated alkaline solution converts the remaining siliceous minerals into bulky alkali silicate gel. The resultant expansive pressure is stored in the aggregate.

The accumulated pressure cracks the aggregate and the surrounding cement paste when the pressure exceeds the tolerance of the aggregate.

Sustainable studies: In this study, sustainable studies of LWGPC have been conducted.

Compressive strength at 28 days ambient curing is 52.9 MPa.

Percentage of water absorption of the GPC is 3.463 per cent.

The average coefficient of permeability of the GPC is 1.187 x 10-9m/s.

The average coefficient of sorptivity is 0.0356 mm/min1/2.

In comparison to the strength of the GPC cured in ambient temperature, the weight loss and strength changes in the specimen when subjected to elevated temperature are as seen in Table 2.

Cost, challenges and availability: As we know, fly-ash is abundant in the country, and being a waste material, it is cheap as well. Granulated furnace slag is obtained in coarse sand form, which is why, it is further processed to get a powdered form for GGBFS. As GPC can cure in ambient temperature and atmosphere, curing problem can be eliminated. In India, some private companies are using geopolymer concrete for pavement decks and paver blocks. However, it has some difficulties in gaining popularity, as it has an entirely new method for mix design and to cast. It is also not familiar to field engineers, but is well-known in research institutes. As GPC experiences some difficulties on the field, especially to handle mixing, not many skilled workers are found on construction sites. Owing to this problem, engineers are hesitating to implement GPC on the field. Only after practical examples for the implementation of GPC are available in local areas, will it be implemented on a large scale across India.

- Seraphina D´souza

To share your experience and insights on an interesting construction material, write in at feedback@ConstructionWord.in

With enormous advantages, geopolymer concrete has a wide scope for implementation in the building, construction and infrastructure spaces. The use of alkali materials and alumino-silicates to form cement is broadly referred to as 'geopolymer' technology, but is also known as alkali-activated cement and inorganic polymer concrete in various parts of the world. In 1978, French materials scientist Dr Joseph Davidovits first coined the term ´geopolymer´, stating ´Raw materials used in the synthesis of silicon-based polymers are mainly rock-forming minerals of geological origin, hence the name geopolymer.´ Geopolymer technology provides comparable performance to traditional cementitious binders, but with an added advantage of significantly reduced greenhouse emissions, increased fire and chemical resistance and waste utilisation. Dr Karthikeyan Jayakumar, Assistant Professor, Department of Civil Engineering, NIT-Trichy, a PhD in structural engineering from IIT-Roorkee, with an ME (structural engineering) and BE (civil engineering), shares more on the material and its advantages. Application in building, construction and infrastructure: Some of the properties of geopolymer concrete (GPC) are fire-resistance, low drying shrinkage, high early strength and toxic material encapsulation. Owing to these properties, geopolymer concrete has various applications in construction, including pavement bricks, precast beams, fire-resisting composite walls, retaining walls, and radioactive and toxic waste encapsulation. Supporting materials and manufacturing process: In a study, materials used to manufacture lightweight geopolymer concrete (LWGPC) included fly-ash and ground granulated blast-furnace slag (GGBFS) as binders, fly-ash pellets as coarse aggregates, bottom ash as fine aggregates, sodium hydroxide and sodium silicate as binder agent and super plasticiser. Preparation of fly-ash aggregates by pelletisation: Pelletisation is the process of consolidating finer moisturised particles into a larger solid material without application of external force. The pellets formed, attain sufficient strength by the force generated inside the mixer. The aggregates are produced by using ´drum pelletiser´. The efficiency of the pelletisation depends on the angle of orientation and speed of the drum. A tilt of 36oand a rotational speed of 200 rpm were adopted for pelletising. Blade orientation, angle of tilt, the rotational speed of the pelletiser and the pellet formation are shown in (Figure 1, Figure 2, Figure 3 and Figure 4), respectively. After the pelletisation, these aggregates are to be cured. Here, chemical curing is adopted using 8M NaOH solution (Figure 5). The aggregates are dipped into the solution and kept for seven days. After seven days, the aggregates are left to dry in ambient atmosphere. Preparation of alkaline solution: Sodium hydroxide pellets and sodium silicate solution were mixed to obtain alkaline activator solution. As a reaction creates hot fumes, it takes a day for the solution to cool down. So, the solution should be mixed one day prior to casting. The ratio to be kept for NaOH by Na2SiO3 is 2.5. The specific gravity of the solution can be calculated by 1.49. Mix proportion: The final mix proportion for cubic metre volume sample: Weight of fly-ash aggregate: 851.972 kg. Weight of bottom ash: 568.16 kg. Weight of fly-ash: 308.46 kg. Weight of GGBFS: 132.2 kg. Weight of NaOH: 44.07 kg. Weight of Na2SiO3 : 110.16 kg. Weight of alkaline solution: 154.23 kg. Weight of superplasticiser: 6.6099 kg. Extra water to be added: 22.033 kg. How does it work? Geopolymer, an amorphous material (at room temperature), consists of a polymeric Si-O-Al framework, similar to that of zeolites, which is a crystalline material. Applications with geopolymer cements and concretes lead to the introduction of user-friendly systems, as it has been noticed that the manufacture of geopolymer cements emits 80-90 per cent less CO2 (greenhouse effect gas) than Portland cement. According to TF Yen, ´a geopolymer is essentially a mineral chemical compound or mixture of compounds consisting of repeating units; for example, silicon-oxide (-Si-O-Si-O-), silicon-aluminate (-Si-O-Al-O-), ferro-silicon-aluminate (-Fe-O-Si-O-Al-O-) or alumino-phosphate (-Al-O-P-O-), created through a process of geopolymerisation.´ Advantages in the Indian scenario: According to the Ministry of Environment and Forests (MoEF), India produced 163.56 million tonne of fly-ash in 2012-13. Table 1 below shows thermal power generation, coal consumption and ash generation in India for the past two decades. Geopolymer concrete has a wide scope of implementation in future scenarios. It is prepared from natural material rich in silica and alumina. It can utilise a lot of waste material as 95-98 per cent of it is fly-ash alone, which is a unique way of disposing waste material. LWGPC will reduce the dead load of the structure. Geopolymer has low heat of hydration and less setting time. It has great resistance to heat and chemical exposures. These are some of the properties of GPC for which it can gain popularity as a smart building material. Shortcomings in usage: The shortcoming occured when the geopolymer concrete was prepared using Rice husk ash pellets. The bonding between the geopolymer matrix with Ricehusk ash pellets was very poor.The seven days compressive strength of the LWGPC was found to be 1.44 MPa, which is 94 per cent less than that of control mix (27MPa), as shown in Figures 8 and 9. The seven days´ compressive strength of the LWGPC was found to be 1.44 MPa, which is 94 per cent less than that of control mix (27 MPa). The reduction in the compressive strength is owing to the alkali-silica reaction (ASR). The ASR is a reaction that occurs over time in concrete between the highly alkaline cement paste and reactive non-crystalline (amorphous) silica, which is found in many common aggregates. This reaction causes the expansion of the altered aggregate by the formation of a swelling gel of calcium silicate hydrate (C-S-H). This gel increases in volume with water and exerts expansive pressure inside the material, causing spalling and loss of strength of the concrete, finally leading to its failure. The mechanisms of ASR are as follows: The alkaline solution attacks the siliceous aggregate, converting it to viscous alkali silicate gel. Consumption of alkali by the reaction induces the dissolution of Ca2+ ions into the cement pore water. Calcium ions then react with the gel to convert it to hard C-S-H. The penetrated alkaline solution converts the remaining siliceous minerals into bulky alkali silicate gel. The resultant expansive pressure is stored in the aggregate. The accumulated pressure cracks the aggregate and the surrounding cement paste when the pressure exceeds the tolerance of the aggregate. Sustainable studies: In this study, sustainable studies of LWGPC have been conducted. Compressive strength at 28 days ambient curing is 52.9 MPa. Percentage of water absorption of the GPC is 3.463 per cent. The average coefficient of permeability of the GPC is 1.187 x 10-9m/s. The average coefficient of sorptivity is 0.0356 mm/min1/2. In comparison to the strength of the GPC cured in ambient temperature, the weight loss and strength changes in the specimen when subjected to elevated temperature are as seen in Table 2. Cost, challenges and availability: As we know, fly-ash is abundant in the country, and being a waste material, it is cheap as well. Granulated furnace slag is obtained in coarse sand form, which is why, it is further processed to get a powdered form for GGBFS. As GPC can cure in ambient temperature and atmosphere, curing problem can be eliminated. In India, some private companies are using geopolymer concrete for pavement decks and paver blocks. However, it has some difficulties in gaining popularity, as it has an entirely new method for mix design and to cast. It is also not familiar to field engineers, but is well-known in research institutes. As GPC experiences some difficulties on the field, especially to handle mixing, not many skilled workers are found on construction sites. Owing to this problem, engineers are hesitating to implement GPC on the field. Only after practical examples for the implementation of GPC are available in local areas, will it be implemented on a large scale across India. - Seraphina D´souza To share your experience and insights on an interesting construction material, write in at feedback@ConstructionWord.in