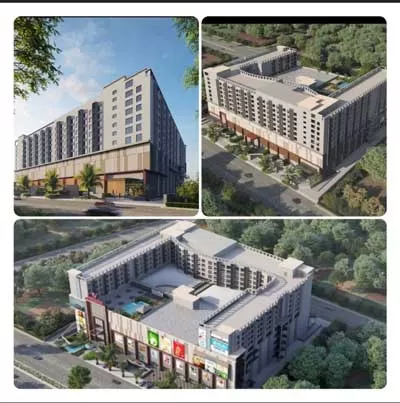

Manglam, Fern Hotels Sign 200+ Key Apart’otel in Jaipur’s Pinkwalk

Manglam Group has signed a 200+ key serviced apart’otel under the Fern Habitat brand in Jaipur, marking a key milestone in its Rs 10 billion hospitality investment strategy. Located within Pinkwalk, Manglam’s flagship mixed-use development in Jagatpura, the project will cater to both short and extended-stay travellers with apartment-style units paired with hotel services. The Fern Habitat Pinkwalk will offer fully serviced accommodations with kitchenettes, daily housekeeping, and on-site dining. The concept blends the independence of apartment living with the comfort of hotel-grade am..

Schon Doorways Launches Monsoon-Ready Aluminium Casement Windows

Schon Doorways, a premium player in doors and window solutions, has launched its new range of aluminium casement and sliding windows, designed specifically to endure the Indian monsoon. Engineered with high-performance tempered glass and ultra-slim aluminium profiles, the windows combine aesthetic appeal with monsoon resilience. Available in single and double track options, the windows offer anti-collision strips, flyscreens, and high load-bearing strength—providing protection against heavy rains, strong winds, and pests. Wall thickness ranges from 1.6 mm to 5.00 mm, offering flexibilit..

LG Charts Global HVAC Leadership With AI, Acquisitions and Localisation

LG Electronics has unveiled a strategic roadmap to transform its ES Company into a top-tier global HVAC solutions provider by 2030, targeting KRW 20 trillion in revenue. The plan, announced at LG Sciencepark, South Korea, focuses on expanding B2B industrial sales, advancing AI-based technologies for data centres, and strengthening localised operations across key regions. Central to LG’s roadmap is growth in the fast-expanding data centre cooling segment. With the global chiller market projected to reach USD 12 billion by 2027, LG aims for KRW 1 trillion in sales by 2027. The company has..