Construction is expensive. A major part of that expense are the physical assets that a construction company or contractor owns or leases. These assets can encompass everything from heavy lifting equipment and heavy construction vehicles, to lighter vehicles (on and off-road) and other machinery and equipment, such as generators and lighting equipment. Then there are multiple portable tools that are a mainstay of any construction site.

All these assets require tracking if a company is to maximise their utility and prevent their theft or misuse. This article will provide a brief overview of the benefits for asset tracking for construction equipment, types of asset tracking, and how to implement a simple tracking system.

Benefits of asset tracking in construction

The most obvious benefit of having asset tracking for construction equipment is to know exactly what asset is where and if it is being used. This is especially important for capital-intensive equipment in use or on site, including bulldozers, excavators, cranes, and front end loaders.

Specific benefits derived from intelligent tracking include:

- improving asset utilisation

-

improved MRO inventory control and forecasting

- more efficient operations

-

lower insurance costs

- better allocation of maintenance resources

- loss prevention

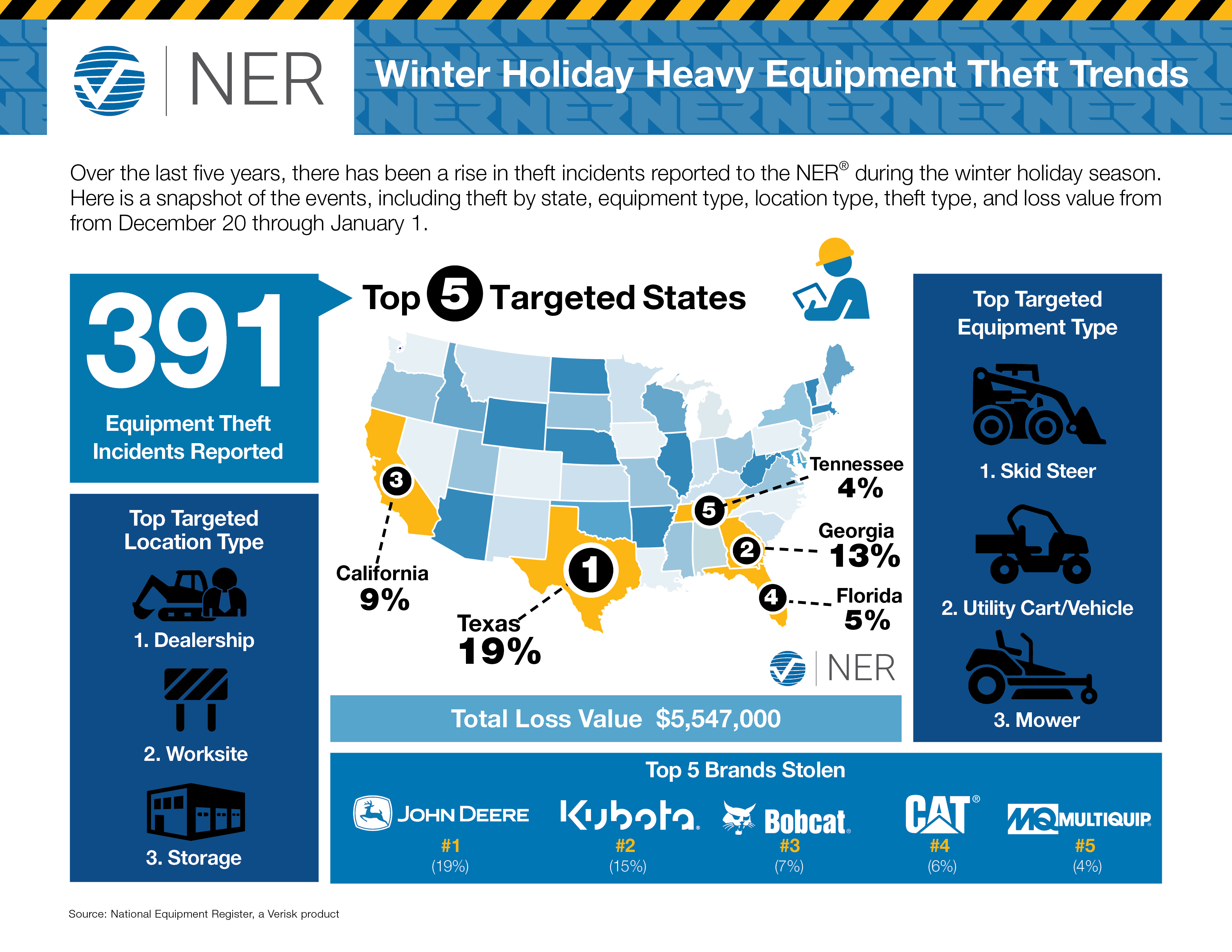

Equipment theft is a significant headache for some construction companies. It can be even be seasonal, as seen in the graphic below regarding equipment theft over the 2019 year-end holiday season, as reported by the National Equipment Register (NER):

Loss prevention doesn’t only mean stolen machinery or equipment, but other types of ‘loss’ too like the pilferage of fuel or substitution with lesser tools (e.g. with ‘home’ tools). Asset tracking can help alleviate some of these concerns.

Types of asset tracking

There are two principal types of asset tracking. The first category is asset tracking hardware, of which the four most common examples are:

-

GPS trackers: cellular technology is used for precise geo-locating, and is particularly useful for tracking heavy and mid-sized mobile equipment (also known as fleet trackers).

- BLE Beacons: Bluetooth Low Energy (BLE) tracking is picked up via a reader or hub within close range of an asset, and is useful for smaller, less mobile equipment.

- QR Tags: Quick Response (QR) tags or codes require manual scanning and can be useful for tracking small assets like tools.

- RFID Tags: Using electromagnetic impulses, radio-frequency identification (RFID) tags capture assets read by RFID readers and are most useful for storage and inventory control of smaller assets.

The second category is asset tracking software. It’s not enough to simply have hardware tracking your assets - software that complements and maximises said hardware is critically important too. Whatever software is chosen (and there are plenty of options specifically for the construction industry), it needs to have sound data collection and analysis capabilities. What you don’t need is a data dump that overwhelms your company!

Implementation of asset tracking in construction

Asset tracking is an important part of construction asset management. There are three main points that need to be considered regarding implementation of an asset tracking program:

1. Be inclusive

Asset tracking needs to ensure the inclusion of all equipment and machinery on a construction site you want to track. That is why a fully integrated asset register is so important.

2. Combine tools and procedures

Your asset tracking system should be as dynamic and innovative as logistically and financially feasible for your company. You will have to use some type of software solution to accurately keep track of your tools and equipment.

Larger equipment and assets that you retrofit with GPS trackers can be easily tracked with a computerised maintenance management software or a fleet management software.

Tracking tools and equipment that exchange hands is more difficult. Alongside equipment or tool tracking software, companies need to implement proper procedures for taking the tools out of the inventory, handing them over to someone else, and returning them to inventory. It doesn’t have to be anything special - you just want to make sure that the location marked in the software is as up-to-date as possible.

3. Be systemic

Asset tracking should be done within a proper systemic context. The project can be realised in phases. You can run a pilot project on a few assets and later expand it to the whole fleet. Following the simple principles of a PDCA (Plan-Do-Check-Act) approach means your asset tracking has a better chance of adding real, risk-savvy value to your company.

Asset tracking of construction equipment is clearly important for a variety of different reasons - whether financial, logistical or project-related. Fully understanding all types of asset tracking and necessary implementation steps is the first step on the road to successful implementation.

About the author:

Bryan Christiansen is the founder and CEO of Limble CMMS. Limble is a modern, easy to use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organise, automate, and streamline their maintenance operations.