In India, the use of blast-resistant design and technology was hitherto limited to petrochemical and nuclear facilities. However, with mounting incidents of explosions caused by industrial accidents and terrorist activity, the need to extend their usage to public buildings and infrastructure facilities has become vital, writes

JANAKI KRISHNAMOORTHI.

In general, blast response mitigation strategy involves incorporation of blast-resistant design and advanced engineering materials and technology with an overall aim to reduce damages caused by explosions. However, there is no universal design solution as it varies depending on factors such as the project layout, the premises usage and type of explosive threat-the underlying principle, of course, is to prevent the overall collapse of the structure.

Fundamental factors

"Blast-resistant design involves many aspects starting from conceptualisation to planning the project layout and design of all areas including the structures, systems, facilities and even landscaping," explains Arun Mull, Director, Tata Consulting Engineers Ltd, and President, Consulting Engineers Association of India (CEAI). "For instance, protective external barriers like fountains, planters and fences serve as obstacles to ramming vehicle bombs. With regard to the building per se, the structural elements of the ground floor plus a few stories above should be designed to withstand a blast. In addition, blast and fragment-resistant materials must be used for non-structural elements like external walls, cladding, doors and windows."

In the petrochemical, nuclear and allied areas, the materials within determine the design strategy, according to Prabhakar Gundlapalli, Additional Chief Engineer (Civil), Nuclear Power Corporation of India Ltd. "The inventory of material prone to explosion is the basis for design and thus takes into consideration the calorific value of the inventory and potential to generate shockwave and fireball, etc," he says. "The effect is simplified in terms of equivalent TNT amount and resulting over-pressure and time of travel of shockwave towards the structure under consideration. Recent research and development in this area led to an equivalent 'TNO Multi-Energy Approach'. But the classical approach of equivalent TNT is widely used. Computational fluid dynamics (CFD) can take care of range analysis and there are multiple case studies where costs have reduced owing to a large number of full-scale experiments."

Gundlapalli, however, maintains that blast-resistant design and technology in India requires an upgrade. "It is not on par with international standards," he concedes. "Even international state-of-the-art technology is mostly seen within the defence sector and the finer details are classified in nature. Indian experience in chemical and other allied industries is limited and needs considerable research, including full-scale experimental studies."

Material match

There are several materials that help increase resistance to blasts, from hig- strength cements, steel hollow sections and mechanical rebar splices to multifilament polypropylene fibres, steel fibres and blast mitigation coatings. "In a blast, about 80 per cent of casualties and damage is because of flying debris. Along with the right design, it is the composite and combined strength of different materials that hold the fragments from flying in the air. For instance, our product blast mitigation coating Paxcon holds all the fragments within itself, thus minimising loss, and delays the possibility of the structure falling owing to its own weight. Our coatings are extremely light in weight and stronger than steel when it comes to flexing," says Hemant Chandak, Chief Executive Officer, Horizon Scope and Trades Pvt Ltd, which markets Paxcon and other products of Line-X, USA, in India.

In addition, the company undertakes study and design for blast-resistant structures in association with Baker Risk & Engineering Consultants, USA.

Regulation revision

The guidelines for blast mitigation design in India also need to be updated. The Bureau of Indian Standards (BIS) issued a standard titled 'Criteria for Blast-Resistant Design of Structures for Explosions above Ground in 1968 and reaffirmed it in 2003.

"The current Indian code IS: 4991-1968 deals only with the mathematical calculations for design and empirical guidelines for some elements," points out Mull. "The techniques and methods for analysis and design have undergone a sea change with the usage of the finite element method of analysis and 3D simulation techniques by using CFD. Hence, the code must incorporate the requirements beyond mere structural design, like aspects of physical security design, criteria for various facilities, anti-terrorism standards for buildings, design of buildings to resist progressive collapse, and design for internal blasts. This requires a shift in emphasis from strength criteria to performance-based criteria. A committee is being formed to draft recommendations to revise the current code and take it up with BIS." Evidently, blast-resistant design and technology still have a long way to go in India.

CASE STUDIES

Blast-resistant design of structures

"The analysis and design of structures subjected to blast loading require detailed understanding of the blast phenomena and the dynamic response of various structural elements," says Rajiv Iyer, Manager - Civil, Nuclear & Special Projects Business Unit, Tata Consulting Engineers Ltd. "These two case studies outline the practices and procedures used in the analysis, design and detailing of a structure and some components subjected to blast loading."

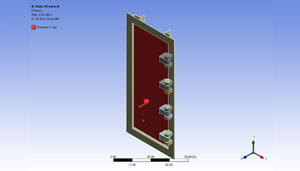

Case Study 1: DESIGN OF STEEL DOOR

Input Data:

- Size of door: 1,200 + 3,000 + 36 mm

- Distance of explosive from door: 285 mm

- Material of explosive: TNT

- Weight of explosive: 3.5 kg

- Material of door: ASTM 36

Methodology:

- Generation of pressure-time curve owing to explosion of TNT using LS-Dyna

- Analysis of steel door in ANSYS for peak positive pressure

- Analytical calculations of steel door using UFC-340-02-2008 (to corroborate the FEM results from ANSYS)

Design criteria:

- Design as per UFC-340-02-2008 Von Mises Stress: 50 ksi

- Allowable support rotation: 4°

Results:

Stresses and support rotation induced in the steel door for external blast of TNT explosive were found to be within acceptable limit of 50 ksi and 4° respectively. Hence, steel door can withstand the blast loading.

Case Study 2: DESIGN OF STEEL LOUVERS

Input data:

- Distance of explosive from louver: 70 m

- Blast charge: 1,000 lb

- Atmospheric temperature: 50° C

- Mach number: 1.085

- Material of louver: Grade-43 of BS4360

Calculation of design pressures:

- Calculating scale distance and time on the basis of inverse scaling laws

- Obtaining Pso, qo to and td from tabulations given in IS 4991

- Estimating Pro based on ratio Pso/Pa

- Calculating shockwave velocity (U)

- Computing clearance distance (S) and time (tc)

- Plotting a bilinear pressure diagram considering Cd = 1

- Calculating the impulse (Iw) for this bilinear variation and effective duration (te)

- Getting the equivalent triangular pressure pulse diagram

Structural analysis:

- Structural analysis for louvers involved transient response calculations

- Analysis based on procedure given in ASCE - Design of Blast Resistant Buildings in Petrochemical Facilities wherein the structure under consideration is transformed into an equivalent single degree of freedom (SDOF) system for dynamic response calculations

- Structural damping considered as zero

Results:

Support rotation and ductility ratio of the louvers are within acceptable limits. Hence, they can withstand the design blast loading

Conclusion:

The structures in above case studies were analysed for blast loading using the SDOF approach. The design adequacy of these structural systems was checked by comparing the support rotations and ductility ratios obtained with the permissibles specified. It was observed that the support rotation and ductility ratio induced in the structural systems were within the permissible limits and hence safe to withstand the pressure generated by the blast.

To share your latest technology with us, write in at feedback@ASAPPmedia.com