- Home

- Building Material

- Steel

- Readyfixing it the right way!

Readyfixing it the right way!

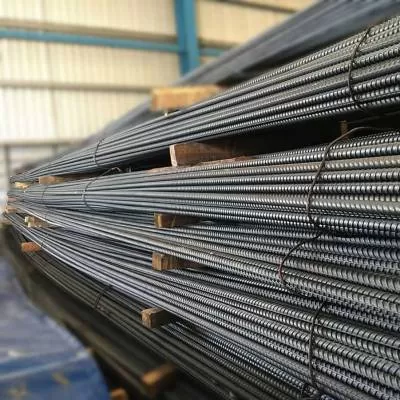

Sunvik Steels Pvt Ltd, a primary steel producer has carved a niche for itself with its unique, premium range of Sunvik Gold XX 500 TMT bars. Its emphasis on excellence of quality is evident in all its products, and now Sunvik Steels launches Readyfix solution as a process towards forward integration.

Market stand-out

Sunvik´s ´Readyfix´ is an effort to simplify and strengthen hassle-free construction process. It is made with accurate angles and lengths, as per the BIS standards. The 135 angle bend and 75 mm length cut, helps the stirrups to hold on tightly with the straight rods in columns, which in turn gives more withstanding capacity to the structure in events like earthquakes.

Absolute precision

Readyfix addresses the challenges in construction, such as unskilled labour, inaccurate measurements, manual cutting and bending, etc. Some advantages are its superior build quality, improving inventory, offering better health and safety at site, avoiding wastage, easy procurement, reduced labour dependency, and freedom in designing. By using Readyfix, customers reduce the problem on the labour front. Besides, it also increases the efficiency on the time lines.

Cost effectiveness:

Readyfix could save around 5-7 per cent cost in steel, which takes into account reduced wastage, lower cutting and bending labour cost, lower inventory carrying cost and pilferage and overlapping. Readyfix can save up to 50 per cent of the costs incurred in cutting, bending and laying, and in addition, gets the advantage of timely completion of the project and hassle free steel procurement.

Green element:

Readyfix is primarily manufactured using Sunvik Gold XX 500 TMT bars, adopting key measures in the overall manufacturing process to lower the greenhouse gas emissions that contribute to climate change. Also, there is no scrap generated at site, hence there is no wastage.

Sunvik Steels´ Readyfix solution helps make the construction process hassle-free. Sunvik Steels Pvt Ltd, a primary steel producer has carved a niche for itself with its unique, premium range of Sunvik Gold XX 500 TMT bars. Its emphasis on excellence of quality is evident in all its products, and now Sunvik Steels launches Readyfix solution as a process towards forward integration. Market stand-out Sunvik´s ´Readyfix´ is an effort to simplify and strengthen hassle-free construction process. It is made with accurate angles and lengths, as per the BIS standards. The 135 angle bend and 75 mm length cut, helps the stirrups to hold on tightly with the straight rods in columns, which in turn gives more withstanding capacity to the structure in events like earthquakes. Absolute precision Readyfix addresses the challenges in construction, such as unskilled labour, inaccurate measurements, manual cutting and bending, etc. Some advantages are its superior build quality, improving inventory, offering better health and safety at site, avoiding wastage, easy procurement, reduced labour dependency, and freedom in designing. By using Readyfix, customers reduce the problem on the labour front. Besides, it also increases the efficiency on the time lines. Cost effectiveness: Readyfix could save around 5-7 per cent cost in steel, which takes into account reduced wastage, lower cutting and bending labour cost, lower inventory carrying cost and pilferage and overlapping. Readyfix can save up to 50 per cent of the costs incurred in cutting, bending and laying, and in addition, gets the advantage of timely completion of the project and hassle free steel procurement. Green element: Readyfix is primarily manufactured using Sunvik Gold XX 500 TMT bars, adopting key measures in the overall manufacturing process to lower the greenhouse gas emissions that contribute to climate change. Also, there is no scrap generated at site, hence there is no wastage. (Communication by the management of the company)