From managing people to processes, Lean deploys numerous tools to ensure the objective of continuous value creation.

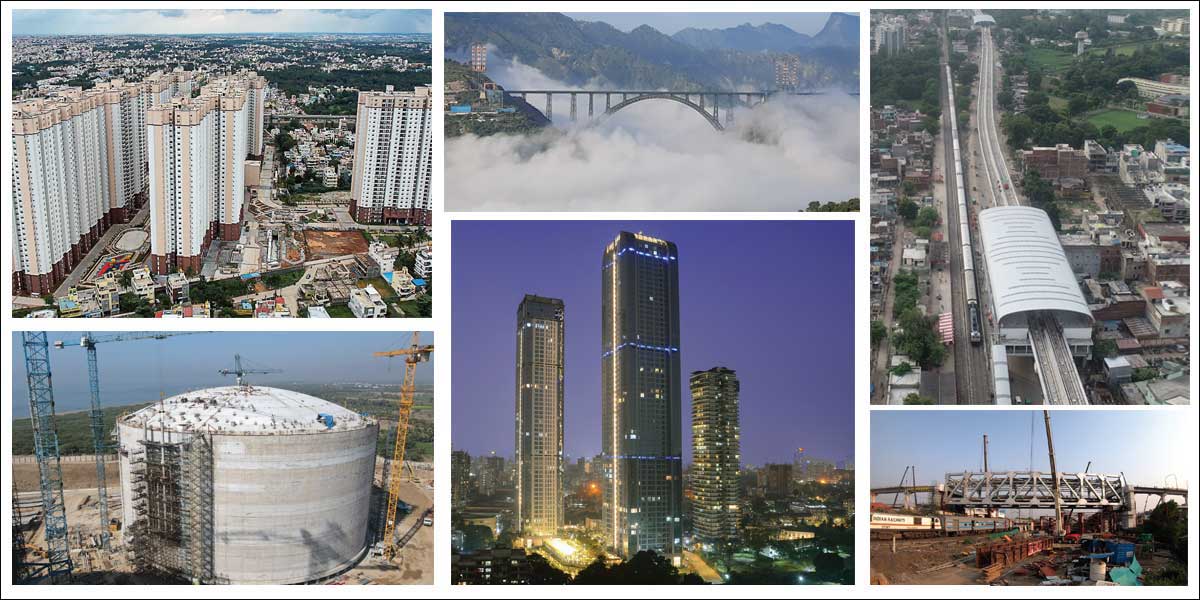

As the pace of infrastructure building scales up in India, there are multiple issues which come to the fore. The idea is to build better and deliver projects on time. But while we are at it, the idea is also not to forget that humans are a key asset in this process too.

“While studying the concepts, methodologies of the process, and the tools of Lean,” says Devarajan Chinnusamy, Chairman and Managing Director, URC Construction “I was confident, if this process is followed as a culture, it can bring back the wonderful ecosystem of workers’ relationships, efficient outputs, their welfare. Moreover the company’s profitability too can be achieved with ease and comfort. Hence, we started implementing Lean with dedication and commitment in all our projects.”

Creating a wonderful ecosystem for all stakeholders to communicate effectively is essential for almost any project that comes to fruition. In infra space its importance can be gauged from the fact that Prime Minister Narendra Modi while inaugurating GATI Shakti had said its aim was to break departmental silos and ensure people work in tandem.

At the ground level this involves people management in a holistic way and Lean construction can play an important role in doing so. It can help in overcoming ‘silo thinking’, bring the ‘no blame culture’ within the project team, build a dedicated and committed team by ‘keeping up the promises’ and enhance the PPC (Percent Plan Complete) through a collaborative planning process.

“Lean focuses more on process management than on production management and works across people, process and technology,” says Professor N. Raghavan, FNAE, FICE(UK), FIE(I) Professor OF Practice– IIT Madras, Member of the Board- Institute for Lean Construction Excellence “Lean construction is more of a construction culture based on concepts such as focusing on value for the client, elimination of wastes, continuous improvement, collaborative working, holistic approach, ensuring overall flow of work and respect for people. Lean also deploys many tools developed in the process to ensure the objective of continuous value creation.”

The nation has much to gain from Lean construction since it can help apex infrastructure enablers in the country to perform better “With successful implementation of Lean methodologies,” says Puneet Narang, Co-lead Infrastructure Sector and Projects Transformation - Business Consulting, Partner, KPMG India, “National Highways Authority of India (NHAI) can improve quality of DPRs, address project related delays by streamlining interdependencies, improve construction quality, improve toll collection and minimise contractual damages and litigation.”

Moreover, as the construction landscape keeps evolving and the infusion of digitalisation keeps increasing Lean will become even more relevant. R. Shankar Narayanan, Head, Corporate Centre, Buildings & Factories (B&F) vertical, Construction Division, Larsen & Toubro; Director, ILCE points out “We are exploring various avenues in digital technologies to work as a catalyst between Lean and practical construction project execution scenarios; to build common data environments with the likes of BIM, AR/VR, digital twins, 3D & visual analytics for progress monitoring and robotics to perform repetitive tasks. Digitisation & Lean Journey for any organisation is intricately inter-twined to achieve a common goal to improve productivity, reduce wastage, optimise processes and enhance efficiency.”

ILCE- Institute for Lean Construction Excellence- is the prime body in India, which was set up with the specific purpose of developing, spreading and nurturing Lean construction practices in the country.After the highly successful national conferences ILCC 2015, ILCC 2017, ILCC 2019, ILCC 2021 and the international conferences IGLC 2018 and Lean in Public Sector- LIPS 2019, this year’s conference ILCC 2022 is being held in Hyderabad jointly with NICMAR National Institute for Construction Management and Research. The five-day programme will be held at NICMAR Hyderabad (Shamirpet) from December

13th - 17th, 2022.

In our continual tradition of promoting best practices in the construction industry, Construction World is happy to partner with ILCE yet again. We will focus on the multi-faceted use and impact of Lean across projects of different scale and size using real-world examples from different experts and academicians involved in the construction industry. We have included a few articles in this issue; the rest will be a part of our cover story in the December 2022 issue.