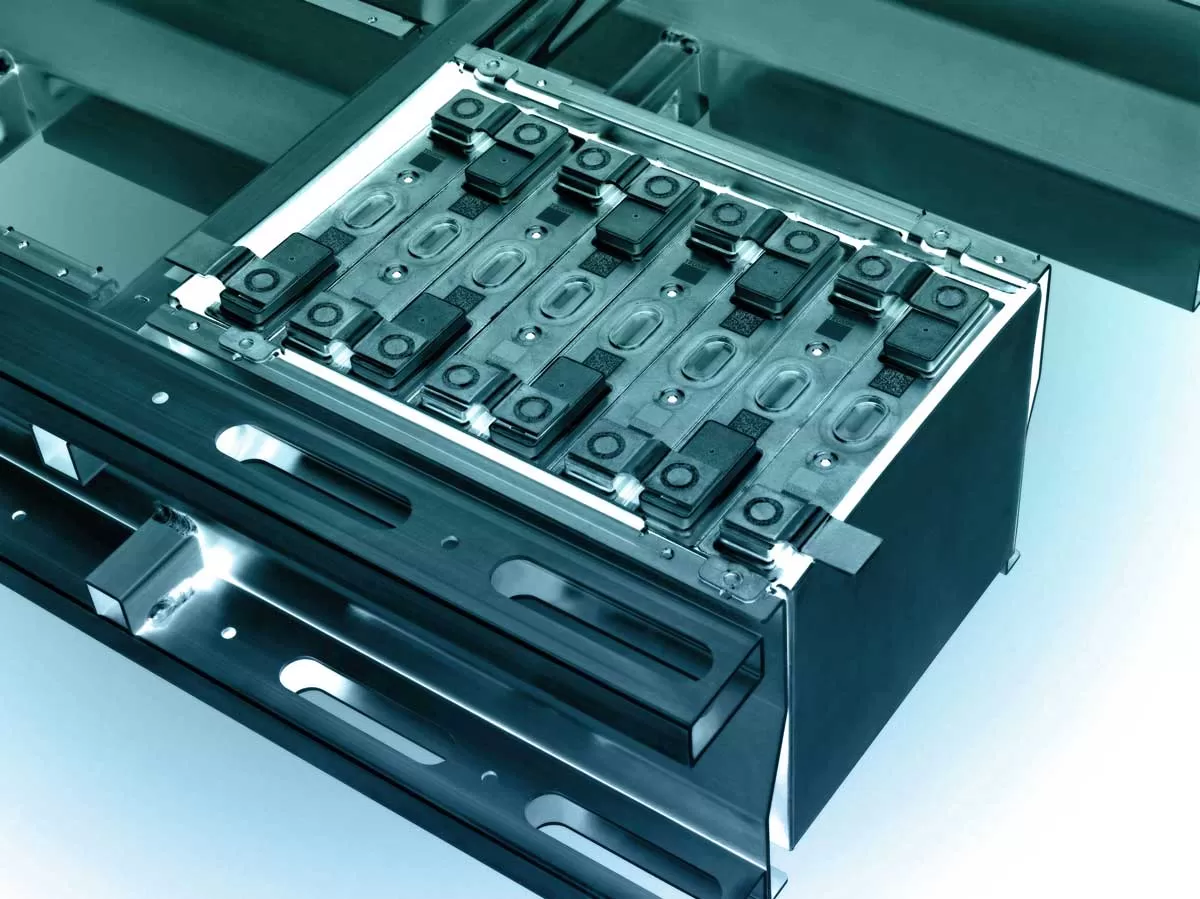

AI-powered laser welding from TRUMPF boosts auto manufacturing quality

Suraj Estate Wins Euromoney Award for India’s Best Residential Developer

"Suraj Estate Developers Limited has received the Euromoney Real Estate Award 2025 for ‘India’s Best Residential Developer’, positioning the company among globally benchmarked leaders in the sector. The recognition reflects its four-decade legacy in delivering high-quality residential and redevelopment-led projects across South Central Mumbai. The Euromoney Real Estate Awards, presented by the London-based Euromoney magazine, are widely regarded as one of the most credible global assessments of performance in real estate, banking and finance. Winners are selected through surveys of inte..

Lloyds Metals, Tata Steel Sign MoU to Explore Strategic Collaboration

"Lloyds Metals and Energy Limited has signed a non-binding Memorandum of Understanding with Tata Steel Limited to evaluate potential areas of strategic cooperation across mining, logistics, pelletisation and steelmaking. The MoU was signed by B Prabhakaran, Managing Director of Lloyds Metals, and Mr T V Narendran, CEO and Managing Director of Tata Steel. The partnership framework aims to leverage the natural operational synergies between both companies and assess opportunities in greenfield steel projects, iron ore mining, slurry pipeline infrastructure, pellet manufacturing in iron ore–ric..

IndiaAI, Gujarat Govt Host Regional Conclave Ahead of 2026 AI Summit

The IndiaAI Mission under the Ministry of Electronics and Information Technology, along with the Government of Gujarat and IIT Gandhinagar, convened a Regional Pre-Summit Event at Mahatma Mandir, Gandhinagar. The initiative is part of the build-up to the India–AI Impact Summit 2026, scheduled for 15–20 February 2026 at Bharat Mandapam, New Delhi. The conclave brought together senior policymakers, technology leaders, researchers and industry practitioners to examine how AI can accelerate economic, digital and social transformation across sectors. The programme focused on the overarching th..