Rosatom Connects First Kursk NPP-2 Unit to National Grid

Rosatom has launched the first power unit of the Kursk Nuclear Power Plant-2 (Kursk NPP-2) into Russia’s Unified Energy System, marking a key milestone in the country’s nuclear energy programme. The initial grid connection took place at the end of the year, bringing a new source of low-carbon electricity online for the Kursk region and the broader Central Energy System.The newly commissioned unit is the first implementation of the VVER-TOI reactor design, which incorporates advanced safety and performance features. With an installed capacity of 1,250 MW, it is the most powerful nuclear pow..

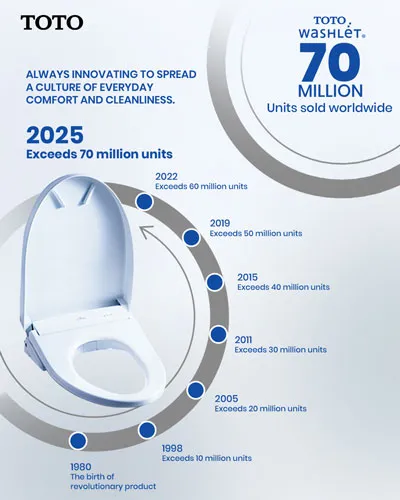

TOTO Crosses 70 Million WASHLET Sales as India Fuels Growth

TOTO has announced that global shipments of its WASHLET range have surpassed 70 million units, marking a major milestone in the brand’s more than four decades of innovation in bathroom hygiene and wellness. Headquartered in Japan, the company supplies WASHLET products across residential and public restroom applications in over 100 countries, with rising demand across the Americas, Europe and Asia.The milestone reflects a global shift toward higher standards of hygiene, comfort and wellness. While overall demand continues to grow worldwide, India has emerged as one of TOTO’s fastest-growing..

Hindustan Zinc, Silox India Boost Low-Carbon Manufacturing Push

Hindustan Zinc Limited and Silox India have strengthened their long-standing partnership with the adoption of Hindustan Zinc’s low-carbon zinc brand, EcoZen, across Silox India’s manufacturing operations. The move marks a key step in advancing low-carbon manufacturing practices and underlines the role of upstream material producers in enabling downstream decarbonisation across India’s industrial value chains.EcoZen is Asia’s first low-carbon zinc produced entirely using renewable energy and carries a verified carbon footprint of less than one tonne of CO₂ per tonne of zinc—around 7..