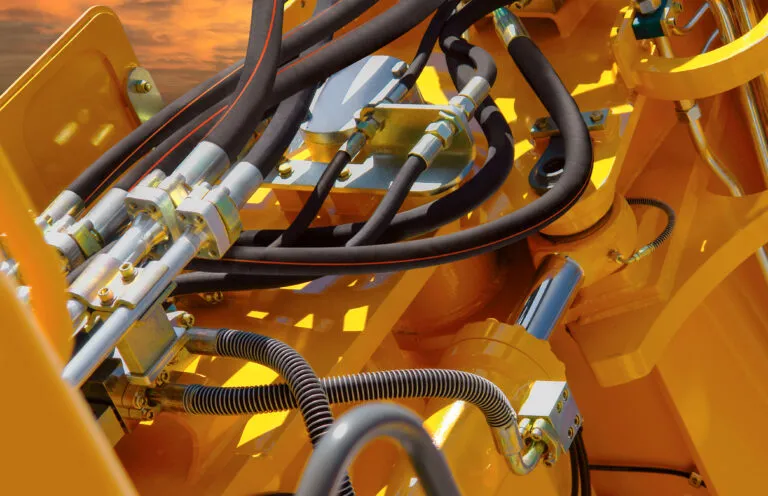

Continental Launches Reduced Dimension Spiral Hoses in APAC

Larsen & Toubro To Divest Nabha Power To Torrent Power

Larsen & Toubro Limited, hereafter L&T, has agreed to divest its entire stake in Nabha Power Limited to Torrent Power Limited, with the companies announcing the transaction. The deal will transfer ownership of the thermal power project and associated assets to Torrent Power as part of L&T's portfolio rationalisation. L&T is a US dollar 30 bn Indian multinational engaged in engineering, procurement and construction projects, hi-tech manufacturing and services across multiple geographies. The company attributes its market position to a strong customer-focused approach and sustained quality over ..

Centre Approves Road Projects Worth Over Rs110 bn

The central government has approved road projects worth over Rs110 bn across Maharashtra, Gujarat and Telangana, according to the Ministry of Road Transport and Highways. The approvals follow a cabinet committee decision and are intended to improve connectivity and reduce travel times on key corridors. The package covers multiple stretches of national highways and involves both construction and widening works. In Gujarat, the ministry approved construction of four-lane sections on the Dhamasiya-Bitada/Movi and Nasarpore-Malotha stretches at a combined capital cost of about Rs45.84 bn. The prin..

Prime Minister Inaugurates India AI Impact Expo 2026

Prime Minister Narendra Modi inaugurated the India AI Impact Expo 2026 at Bharat Mandapam in New Delhi, opening a national platform for Artificial Intelligence (AI) demonstration and dialogue. The event brought together innovators, researchers and technology enthusiasts from across the country and abroad to showcase applications and research. The inauguration underscored the government’s intent to position India as a significant contributor to global AI development. The prime minister noted in a post on X that being among innovators, researchers and tech enthusiasts offered a clear view of t..