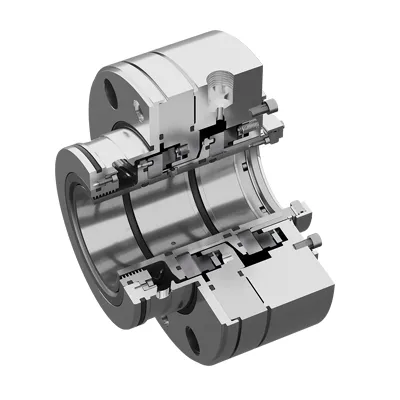

Next-Gen Seal

Type 8628VL is a next-generation mechanical seal for multiphase ethane and ethylene pipelines. Featuring dual non-contacting seal faces with spiral groove technology, it ensures superior reliability, efficiency, and environmental compliance under volatile pressure and temperature conditions, validated by peer-reviewed research.Company Name: John Crane Website: https://www.johncrane.com/ ..

Smart Kitchen Chimney

KAFF’s NEWBURY 90 DC chimney combines sleek grey tempered glass design with a powerful BLDC motor, 8-speed gesture/touch controls, multidimensional extraction, LED lighting, filter-less Smart Auto Clean technology, and a 12-year motor warranty delivering elegance, quiet efficiency, and long-term reliability.Contact: KAFFWebsite: https://shorturl.at/WKUkh ..

Premium Coverage

Nova 125 Premium Gypsum Plaster by Walplast offers 25 per cent more coverage at 125 m² per tonne, ensuring faster application and a flawless finish. With high whiteness, strength, crack resistance, and eco-friendly natural gypsum, it delivers durable, efficient, and sustainable wall solutions.Company: Walplast Website: https://www.walplast.com/ ..